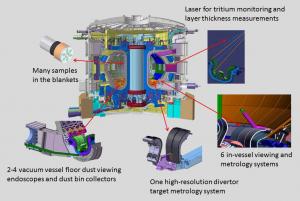

From 12 to 14 February the ITER Diagnostics Division hosted a three-day workshop on erosion, deposition, dust, and tritium diagnostics which was attended by about 30 international experts. The aim of the workshop was to define the relevant suite of diagnostics that will be necessary in the ITER machine.

In ITER, the amount of dust and tritium allowed inside the vacuum vessel is limited by the technical prescriptions from the Regulator. Dust is produced either from the gradual erosion of the plasma-facing first wall elements and the re-deposition of this material inside the vacuum vessel, including some tritium, or alternately by transients, like disruptions which can produce dust in a more concentrated way.

The

decision to use tungsten instead of carbon as divertor target material has reduced the expected dust production by one to two orders of magnitude, so that the dust accumulation is expected to stay significantly below the limits. The workshop included presentations and discussions on the safety limits; newest modelling and experimental results (mainly from JET's ITER-like wall); and the proposed diagnostics, including worldwide experience with similar systems.