The largest pulsed electromagnet ever built

23 Feb 2014

-

Lynne Degitz, US ITER

The modules will be fabricated with a just-in-time process. As each shipment of conductor is received, it will immediately enter the winding station to be formed into pancakes.

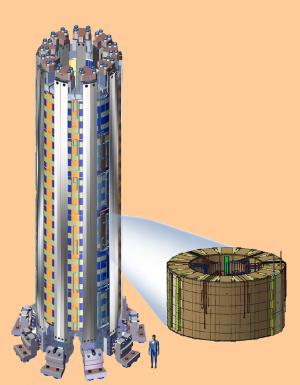

To initiate and maintain plasma current, ITER requires a giant solenoid—which will be the largest pulsed electromagnet ever built. The 1,000-metric-ton solenoid located in the centre of the ITER Tokamak will have 5.5 gigajoules of stored energy and be about 18 metres, or 60 feet, tall.

The Oak Ridge National Laboratory US ITER team leading central solenoid development and fabrication has developed a firm basis for the design and achieved a number of key milestones in the last six months, including a final design review in December 2013. Authorization to proceed to manufacturing is expected in May 2014 from the project's coordinating body, the ITER Organization.

"The central solenoid development has followed a unique process," said David Everitt, the central solenoid system manager. "We brought the fabricator, General Atomics in San Diego, on board early to help with manufacturing review and development. As the central solenoid design progressed, the fabricator has been taking our design, prototyping it and providing feedback."

That approach has helped US ITER resolve a number of engineering challenges. Not only is the central solenoid unusually large and powerful, but it also is tightly integrated into the ITER magnet system.

ITER uses a magnetic confinement approach to contain 100-million-degree-Celsius plasmas within carefully defined magnetic fields. In some locations, there will be only 10 mm of space—the width of a thick pencil—between the massive central solenoid and a 13 metre, or 45 foot, tall "D"-shaped toroidal field magnet.

Wayne Reiersen, the US ITER magnet systems team leader, noted

The 1,000-tonne solenoid located in the centre of the ITER tokamak will have 5.5 gigajoules of stored energy and be about 18 metres, or 60 feet, tall.

that "the actions proposed in the final design review report are thoughtful and provide us with excellent feedback on the central solenoid design and path forward. We will really benefit from this review."

Overall, the final design review confirmed that the central solenoid design is well supported by analysis and by research and development.

The solenoid will be composed of six stacked modules, each made of conductor wound into pancake-like layers. An individual module weighs more than 110 metric tons. The manufacturing process for the modules of the central solenoid will take 16—24 months per module. Each module, plus a spare, must be fabricated and tested at full current, 45 kA, and 4 degrees Kelvin, or about minus 269 degrees C, to ensure that the magnets are ready to perform in the superconducting environment of the ITER machine.

The modules will be fabricated with a just-in-time process. As each shipment of conductor is received, it will immediately enter the winding station to be formed into pancakes. The module fabrication process culminates approximately two years later when the module passes final testing and is shipped to France. Everitt added, "Building the central solenoid is all about timing. At any one time, we can have four or five modules moving through the production process."

A central solenoid mock-up module, which will verify the production process, is planned for completion in summer 2015, with sample conductor winding activities beginning in summer 2014.

The mock-up module will be made at 40 percent of the actual ITER module height and will not be superconducting. The mock-up is a way to commission the central solenoid work stations, the insulation method and the overall process. All of the modules are scheduled for completion by February 2019 to meet the international ITER schedule.