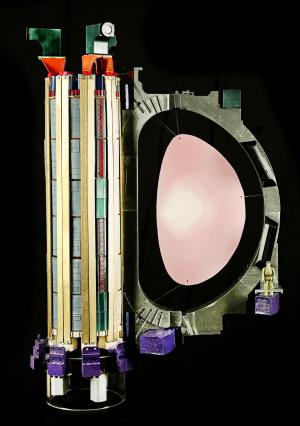

ITER has been called a puzzle of a million pieces. US ITER staff at Oak Ridge National Laboratory are using an affordable tool—desktop three-dimensional printing, also known as additive printing—to help them design and configure components more efficiently and affordably.

"Now for pennies instead of tens of thousands of dollars, we can have impact right away with 3D printing. It lets us see what the part actually looks like," says Kevin Freudenberg, an engineer who supports the US ITER magnets team and has led the project's use of 3D printing. "On 3D CAD (computer-aided design) displays, you can't feel the shape of an object. You just see it. Many people have trouble seeing 3D projections or find them tiresome to view over time. With the 3D printed objects, you can run your finger over the surface and notice different things about the scale and interfaces of the component."

The fusion engineering design process has long relied on mock-ups and prototypes. Full-scale models cast or machined from metal and other materials continue to have value and will still be a part of the US ITER development process, as will 3D computer modelling; however, the affordability and accessibility of desktop 3D printing offers a number of advantages.

Freudenberg said that 3D printing helps mitigate risk: "The models show complexity and help us catch issues earlier in the process."

A normal part of the engineering process is the identification of interferences or design problems before a component is finalized. Mark Lyttle, an engineer working on the pellet injection and plasma disruption mitigation systems for US ITER, observes, "It's a lot more time consuming and expensive when you find that mistake in a metal prototype than it is in a 3D printed component. 3D printing is very low-cost. With metal, you may have to start over if you can't re-machine it."

Gary Lovett, a designer with US ITER, adds, "If you can correct one design and make one revision, you've basically paid for the printer. It's so much more informative, especially if you have assemblies to put together."