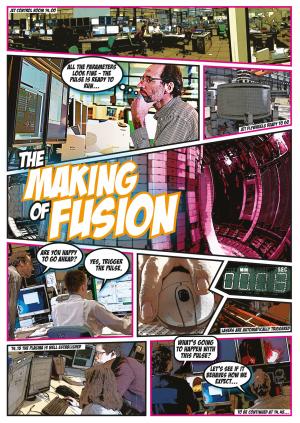

The story of a JET pulse

Unlike future stations when the plasma will need to run for several hours or continuously, on JET, each pulse typically lasts around 40 seconds. Although this may seem like a short amount of time, the 80,000 or so plasmas already created in the machine since 1983 have provided crucial information for plasma science by focusing on its behaviour and improving its performance. The pulses have all contributed to an extensive knowledge bank of data (with over 100 TeraBytes of data collected to date) and their analysis plays a key part in the long-term goal of fusion electricity on the grid.