In 2012, Air Liquide had been awarded the

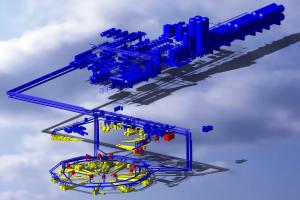

ITER Organization contract for three identical liquid helium (LHe) plants. This most recent contract, worth EUR 65 million, covers the supply of complementary equipment including two nitrogen refrigerators to cool ITER's liquid helium plant and the 80K helium loop boxes, quench tanks, heaters and dryers with nitrogen in liquid or gaseous form, and a purification system.

In a video interview produced by Fusion for Energy, the CEO of Air Liquide Advanced Technologies, Xavier Vigor, says he expects that his company will benefit from the knowledge acquired during the execution of the ITER contracts and that it will increase its competitiveness in two expanding markets important for the future: helium and hydrogen production and transport. "For ITER, we will design and manufacture the biggest cryogenic helium plant in the world—three times bigger than the last [record-holding] plant we manufactured that was already the largest in the world. We will expand our competencies in the cryogenic field and we hope to be able to re-use these competencies and human resources for future projects."

Fusion for Energy Director Henrik Bindslev concurs: "Thanks to ITER, the frontiers of science and technology are pushed further and Europe's industry is becoming more competitive. To be part of the biggest international energy project means being confident enough to put your expertise to the test and brave enough to take it a step further."