European industry to supply divertor remote handling system

8 Jun 2014

The long concept preparation phase for ITER's high-tech divertor remote handling system has come to an end and industry is about to take over, thanks to a seven-year, multimillion-euro contact signed between the European Domestic Agency for ITER and Assystem, a leading consultancy firm in engineering and innovation.

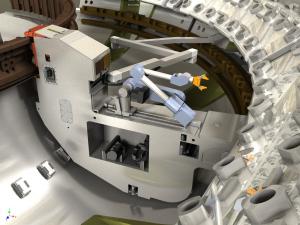

Assystem and its partners will have the responsibility for the design, manufacture, delivery, installation, commissioning and final acceptance tests of the remote handling systems that will be charged with the remote replacement of ITER's 54 divertor cassettes. Running toroidally along the bottom of the vacuum vessel the ITER divertor acts as the Tokamak's exhaust system, extracting helium ash from the burning plasma. Due to the tremendous heat loads and magnetic forces that divertor components will face, replacement is planned three times over the course of the machine's lifetime.

The equipment of the Divertor Remote Handling System will allow for the safe and reliable positioning, as well as extraction, of the 54 removable cassettes. Due to severe space constraints in that part of the vacuum vessel, the remote handling system will have to manoeuvre its heavy loads with extreme precision—respecting positioning tolerances of only a few millimetres at certain points along the transport trajectory.

The ITER team and a number of European institutions have been working on the development of the ITER divertor maintenance concept for more than 15 years. Some of the most challenging steps within the process have been demonstrated at full scale, first within the Divertor Test Platform (DTP) constructed in Brasimone, Italy, and more recently within the DTP2 (Divertor Test Platform 2) located in Tampere, Finland (see video, below).

"This is a very important milestone for the ITER Divertor Remote Handling System," says Jim Palmer, of ITER's Remote Handling Section. "It has been a long road of design, R&D and prototyping to reach this point, and now we are really looking forward to getting down to the detailed design."

Assystem leads a team of well-known experts in the remote handling field, comprising the Culham Centre for Fusion Energy, CCFE (UK); Soil Machine Dynamics Ltd, SMD (UK); VTT Technical Research Centre (Finland); and Tampere University of Technology, TUT (Finland).