Disruption mitigation team reviews progress

19 Sep 2014

-

Lynne Degitz, US ITER

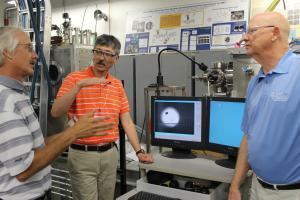

In Oak Ridge National Laboratory's Pellet Lab, Larry Baylor (ORNL), So Maruyama (ITER Organization) and Steve Combs (ORNL) discuss pellet performance; the background screen shows an intact pellet that was shot at approximately 260 metres per second through the pellet selector. Photo: US ITER

US ITER researchers based at the Department of Energy's Oak Ridge National Laboratory (ORNL) are leading the development of a disruption mitigation system to reduce the effects of plasma disruptions on ITER. The US Domestic Agency for ITER signed a formal arrangement with the ITER Organization on 29 July for the work and during the week of 8 September the ITER Fuelling & Wall Conditioning Section leader, So Maruyama, paid a visit to Oak Ridge to assess US progress and plan for an upcoming design review of the ITER disruption mitigation technologies.

"I'm impressed," said Maruyama after his visit to the disruption mitigation and pellet injection team at Oak Ridge. "Only a year or two ago these were rough ideas. Now we have real prototypes that are functioning and being tested, such as the massive gas injection valve and the pellet selector."

"We have a very conservative and flexible approach to disruption mitigation on ITER," said Larry Baylor, a distinguished scientist in plasma technologies and applications at ORNL, "with different locations for material to be injected, different types of material, and different response times. We are also designing the system in a way that will allow for evolution of the mitigation technology."

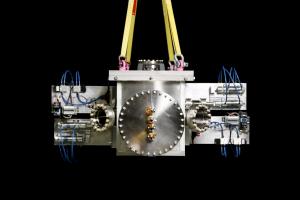

The guide tube selector test unit prototype has now been installed at the ORNL pellet lab for testing. The unit is designed to guide pellets to specific locations in the plasma. Photo: US ITER/ORNL

Two approaches have been developed to help control plasma disruptions: massive gas injection and shattered pellet injection. Both deliver material to the plasma within milliseconds. By injecting material into the plasma, ITER operators will be able to manage plasma energy in a way that lessens thermal loads and mechanical stresses on the plasma-facing components of the machine. The injected material can also inhibit the formation of runaway electrons, which occur when electrons are accelerated from the electric field in the plasma during a disruption.

"This is essential technology development for ITER," noted Maruyama. "Oak Ridge is the expert on the pellet injector and has a long history of contributions to other machines such as JET, DIII-D and LHD."

The development of technologies for ITER disruption mitigation benefits from physics input from around the world, including the ITER Organization, JET and Oak Ridge. The disruption mitigation design is also influenced by ITER experts in vacuum, tritium, cryogenics and port plug integration.

The next major step for disruption mitigation is a system-level design review in November. Maruyama notes that "this review will help us confirm where we are and what we've achieved, and help us try to narrow down options for the path forward."