Trying on the tokamak crown

A crown usually sits on a king's head, or on the top of prestigious buildings such as cathedrals or skyscrapers.

In ITER, the "crown" sits under the machine: it is the structural element that supports the combined mass of the cryostat, vacuum vessel, magnet system and thermal shield—in short, the support system for the 23,000-tonne machine. From both a structural and safety perspective, it is one of the most strategic parts of the installation.

Designing the ITER crown has proved an utterly complex and challenging task, involving several ITER departments as well as experts from the ITER European agency and its architect-engineer Engage.

The crown's complexity stems from the fact that the huge mass that it will support will not be an idle one. In the course of operation, the ITER tokamak might slightly "up-lift", wobble, or shrink...causing considerable load transfers from the machine to the Tokamak Building basemat.

In late 2012, following some ten months of collaborative effort, the crown design was finalized: it will consist of a thick, circular concrete structure connected to the three-metre-thick bioshield by radial concrete walls.

In order to allow for the smooth transfer of horizontal and rotational forces generated by the movement of the tokamak, 18 spherical bearings acting like ball-and-socket joints will be installed between the concrete crown and the steel ring that acts as the interface with the cryostat.

Actual construction, however, is a long way from 3D design documents. When a structural element is as complex and as strategic as the ITER crown, an intermediate step is necessary to demonstrate constructability.

"Just like for the Tokamak Complex basemat slab, we need to be certain that the rebar principles we have opted for are constructible, and we need to qualify the bespoke concrete formula," explains ITER's Nuclear Buildings Section leader Laurent Patisson. "And there's only one way to do this: by trying it first on a real-size mockup."

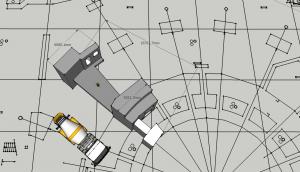

On the very place where the "B2 slab" mockup was standing just a few months ago, a new mockup has been under construction since the end of 2014. When completed, the large structure will reproduce a 20° segment of the tokamak crown, complete with a one-metre-thick radial wall and a three-metre-thick section of the bioshield.