First prototypes of high-voltage feedthroughs

23 Feb 2015

-

Kalpesh Doshi, Superconductor Systems and Auxiliaries Section

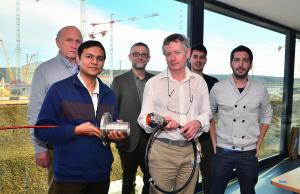

The high-voltage magnet instrumentation team has achieved a critical milestone. From left to right: Adamo Laurenti; Kalpesh Doshi; Arnaud Devred; Jean-Yves Journeaux, Roland Piccin and David Carrillo.

One of the big challenges to the monitoring and protection of the large and complex superconducting components of the ITER magnet system is the transmission of the voltage signals from cryogenic to room temperature in a challenging environment involving high voltage, high vacuum, high magnetic field and radiation.

In ITER, the magnet instrumentation cables extend from the magnet cold mass in the insulation vacuum to the outside world at atmospheric pressure. The transition between vacuum and atmospheric pressure takes place at the level of the so-called instrumentation feedthroughs.

The operating insulation voltage for the feedthroughs varies from 4 kV to 30 kV, derived from the electro-dynamic analysis of the ITER magnetic circuits. Based on these voltage levels and the number of wires in the cables, the feedthroughs are divided in five different types.

Other operating parameters are: vacuum up to 10^-6 torr, magnetic field up to 100 mT, and integrated radiation gamma doses of 1 kGy during the operational life time of the ITER machine (20 years).

The ITER requirements made procuring the feedthroughs challenging, as no commercial solutions were available at the time. Approximately 1,000 units, distributed all around the Tokamak Complex, are needed for ITER.

Detailed R&D programs for the qualification of a prototype design were launched in 2009, followed by the qualification of potential vendors for series production. In 2014, the ITER Organization awarded the contract to Ceramtec North America Corporation (US).

A few design iterations and sub-assembly tests were carried out to optimize design and manufacturing processes. After design approval by the ITER Organization, Ceramtec has produced two samples for the 6 pin 30 KV rating, identified as a type D variant.

The feedthroughs have passed all of the thermal cycle tests and leak tests at various stages of manufacturing and assembly, followed by a final electrical test at Ceramtec. The feedthroughs were connected to prototype high voltage cables provided by ITER for the electrical testing, before being sent to the ITER Organization for additional type tests and further validation.

It was an exciting moment for the ITER magnet instrumentation team when it received the first shipment of two high voltage feedthrough samples! "The sheer size and weight of these feedthroughs give a pretty good idea of the challenges ahead for the installation and commissioning of the high voltage magnet instrumentation. The achievement of this critical milestone and the reception of these two prototypes at ITER show the good and timely progress of the magnet instrumentation team and its readiness to process with series production," says Arnaud Devred, Superconductor Systems and Auxiliaries section leader.

The next steps for these feedthrough prototypes will be a re-check of vacuum leak tightness in the recently set up vacuum lab in the ITER Headquarters basement, and comprehensive high voltage testing at the Magnet Infrastructure Facilities for ITER (MIFI), hosted at the neighboring CEA research centre.