Strong progress in conductor production

The 13th edition of the Conductor Meeting took place in Grindelwald, Switzerland from 17-19 March 2015 with the support of the plasma and fusion laboratory CRPP (Centre de recherches en physique des plasmas, Lausanne.)

Since March 2009, this meeting has been organized on a twice yearly basis to bring together the six Domestic Agencies involved in the procurement of ITER conductors and their suppliers. In recent years, it has been extended to include the actors (Domestic Agencies and suppliers) involved with coil manufacturing to anticipate and/or cope with issues that arise on conductor delivery or acceptance.

The most recent gathering in Switzerland was coupled with a meeting of the SULTAN working group, a long-running expert group in charge of reviewing the results and assessing the performances of full-size conductor sample tests and joint sample tests that are performed at the SULTAN facility in Villigen, Switzerland.

The meeting was a good opportunity to herald the progress in conductor production.

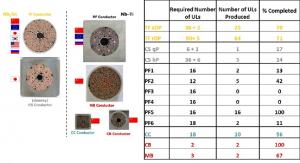

Nearly all niobium-tin (Nb3Sn) superconducting strands for the ITER toroidal field coils have been produced by China, Europe, Japan, Korea, Russia, and the US—about 500 tonnes in all. Seventy percent of the toroidal field conductor unit lengths have now been completed (see chart).

Russia has completed the niobium-titanium (Nb-Ti) superconducting strands for ITER's smallest poloidal field coils, PF1 and PF6, and Europe has begun manufacturing the conductor unit lengths. Two-thirds of the strands needed for poloidal field coils PF2-5 have been manufactured in China, as well as all unit lengths for coil PF5. Japanese and Korean suppliers have manufactured approximately 28 percent of the Nb3Sn superconducting strands required for the central solenoid coils and Japan has completed unit lengths corresponding to one (of six) central solenoid modules.

For the ITER correction coils and busbar conductors, China has produced the full amount (22 tonnes) of Nb-Ti strand; over half of the unit lengths for the correction coil conductor; both unit lengths for the correction coil busbar conductor; and two (of three) main busbar conductor unit lengths.

Progress was also reported during the meeting on coil manufacturing. Europe has wound 23 toroidal field double pancakes while, in Japan, seven double pancakes have been manufactured by one supplier and a second is completing the manufacture of a dummy. Winding qualification activities for the central solenoid modules have been completed in the US and production winding is set to start in the coming weeks; Russia is currently carrying out winding qualification activities for the PF1 coil; and China has completed the fabrication and testing of a pair of high temperature superconductors for the correction coils.

The SULTAN Working Group confirmed the good results of all full-size conductor samples tested as part of the comprehensive quality control plan for ITER conductors. An amendment to the SULTAN contract signed in 2012—currently under preparation—would enable the Domestic Agencies that are still in production a priority use of the facility.

The conductor meetings have been instrumental over the years in building up a project team spirit and mutual trust at the technical level. The next meeting is planned for 21 September 2015 at ITER Headquarters.