Testing cleaning techniques for diagnostic mirrors

8 Apr 2015

-

Angela Saenz, System Management Section

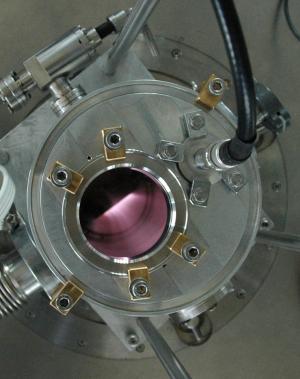

To avoid reflectivity losses in the optical diagnostic systems, a cleaning technique known as "plasma sputtering" is foreseen to remove deposits from the mirror surfaces.

A strong collaboration between the Physics Department of the University of Basel (UniBasel)*, Denmark's Technical University (DTU) and the ITER Diagnostics team has led to important experimental results in the investigation of cleaning techniques for inaccessible diagnostic mirrors inside the ITER Tokamak.

Known as metallic first mirrors, these components are part of optical diagnostic systems that are in place to ensure plasma control and analysis. Their role is to guide the light coming from the plasma or from probing light sources through the neutron shielding towards detectors.

Due to their proximity to the plasma, first mirrors will be exposed to charge exchange neutral fluxes and ultraviolet, x-ray and gamma radiation, which can lead to surface erosion and/or deposition of particles such as beryllium or tungsten from the blanket first wall. To avoid reflectivity losses in the optical diagnostic systems, a cleaning technique known as "plasma sputtering" is foreseen to remove deposits from the mirror surfaces.

The team conducted several experiments at the University of Basel to evaluate mirror cleaning scenarios under different experimental conditions. In a two-stage operation, the team first analyzed the deposition of a particle film on the mirrors (using aluminium instead of beryllium to avoid toxicity), and then the success in removing the film through the application of a direct radio frequency plasma on the mirror. The experiments replicated earlier successful experiments performed on mirrors with a diameter of 25 mm, but were more challenging due to the size of the ITER mirrors (200 x 300 mm).

The effect of magnetic field during the plasma cleaning process was also investigated. At EPFL-CRPP* Lausanne, the cleaning process was evaluated both in the presence of magnetic field up to 3.5 T, and without it, leading to new conclusions that will contribute to further validating the cleaning procedure in the high magnetic fields that will be present in the ITER Tokamak.

For their collaboration in evaluating the efficiency and performance reflectivity measurements in the plasma cleaning process, the UniBasel/DTU/ITER Diagnostics team received a commendation during the ITER Recognition Ceremony held in December 2014.

The team members are Laurent Marot, Ernst Meyer, Lucas Moser and Roland Steiner from the Department of Physics at the University of Basel; Frank Leipold from Denmark's Technical University; and Roger Reichle from the ITER Diagnostics Division.

* In this collaboration, the University of Basel acts as the link to the Swiss partner of the EUROfusion Consortium, the EPFL (Lausanne), where the cleaning process was also evaluated.