Strip off the concrete

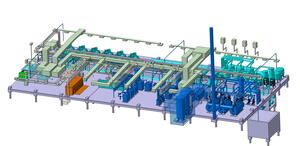

What an unattractive expression for something that is almost artistic: a configuration management model (CMM) describes the required space envelope needed by a system or component taking into account space for maintenance, assembly, inspection and the interfaces with other systems and the buildings.

Recently, significant progress was made by the System Engineering Support team led by Thibault Tsedri in collecting and defining approximately 800 required openings and penetrations in the walls and floor slabs in the Tokamak Complex buildings.

The completion of all the models was a necessary part of confirming that the size and layout of each building is adequate and appropriate for the accommodation of all plant systems. CMMs will also provide the Architect Engineering (AE) contractor with all the necessary information to start the preliminary design of the buildings.

The ultimate milestone will be the signature of the AE contract that will take place on the ITER site next Tuesday, 13 April.