Testing of the magnetic field in the Wendelstein 7-X fusion device has been completed sooner than planned. This fusion device of the stellarator variety located at the Max Planck Institute for Plasma Physics (IPP) in Greifswald, Germany is now in its commissioning phase in anticipation of a first plasma before the end of the year.

The measurements, completed in early July, show that the superconducting magnetic coils are producing the required magnetic field. The magnetic cage for the fusion plasma, which has a temperature of many million degrees, has a configuration that is in line with physicist calculations. This is an essential milestone in the operational preparations that are currently underway.

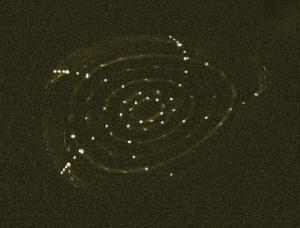

Although Wendelstein 7-X is not yet in operation, the experiment is already providing the first scientific results. The magnetic field meets the precise requirements for the confinement of the high-temperature fusion plasma as demonstrated by the first measurements of the field structure. "We've got nice closed flux surfaces," Thomas Sunn Pedersen, the IPP Division Head responsible for this task, was pleased to announce.

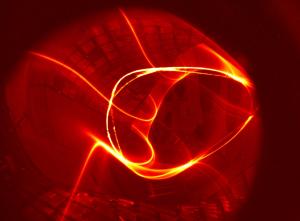

How do you build a magnetic cage for the plasma? Fusion researchers make use of the fact that the charged plasma particles — ions and electrons — are kept on narrow spiral tracks around magnetic field lines by electromagnetic forces. As a result of a suitably formed field, the fast particles, as if guided on tracks, are kept away from the walls of the plasma vessel. To achieve a closed cage, the field lines in the centre of the circular plasma vessel must span closed, nested, circular surfaces like the growth rings inside a tree trunk. This prevents field lines pointing outwards, which would direct the plasma particles against the walls and make it impossible to achieve the high plasma temperatures required.