High-temp superconductor leads pass second qualification milestone

24 Aug 2015

-

Pierre Bauer, Superconductor Systems & Auxiliaries Section

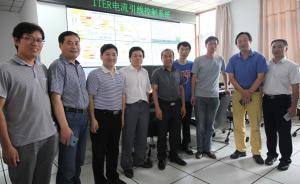

Assembled in the test hall control room at ASIPP (from left to right): ASIPP's Feng Hansheng, Chen Junling, Song Yuntao and Wan Baonian; the head of the Chinese Domestic Agency (CNDA), Luo Delong; ASIPP's Ding Kaizhong (test leader), Zhou Tingzhi (lead manufacturing responsible officer), Li Jiangang; and CNDA's He Kaihui. In the back, the MIMIC screen of the test control system supplied by the ITER Organization.

High Temperature Superconductor (HTS) current leads are key components of the ITER magnet system, transferring the large currents from room-temperature power supplies to very low-temperature superconducting coils at a minimal heat load to the cryogenic system. The HTS current leads for the ITER Tokamak are procured by the Chinese Domestic Agency through the Institute of Plasma Physics (ASIPP) in Hefei, China.

Following the signature of the ITER coil feeder Procurement Arrangement in January 2011, ASIPP launched a string of activities to prepare for series production, which began with the qualification of critical manufacturing technologies through targeted trials in mockups and which will conclude with the manufacturing and testing of several pairs of current lead prototypes this year.

In March, success was reported in tests on a pair of correction coil 10 kA current lead prototypes. More recently, and according to schedule, it was the turn of the toroidal-field-type prototypes. Tested at their design current of 68 kA, the technical challenges were significantly greater than during the previous test. In fact, it was the moment of truth for the ITER HTS current lead designs and for ASIPP's manufacturing team. Once installed in ITER, these leads—each weighing about 1.5 tonnes—will be the largest HTS current leads ever operated.

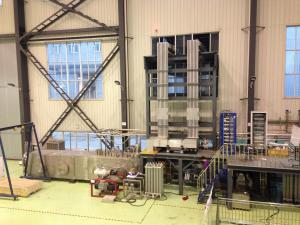

At ASIPP, the prototype toroidal field coil HTS current leads are installed in a prototype coil termination box. Also visible are the aluminium bars connecting the test station to the power supply.

There was indeed reason to celebrate when, at the second attempt, the steady state operation test at 68 kA was successfully completed in early July. Following these tests, a further test program (specified by the ITER Organization) was executed, often late into the night, which included operation at up to 75 kA and so-called LOFA runs in which the response of the lead to an interruption of the cryo supply is tested.

A LOFA time of more than seven minutes was measured for both prototypes under full current. Since the temperature rises in the current leads (as a result of the imbalance between Joule heating by the current and cooling—switched off during the test—in the resistive sections), this process also leads to a quench of the HTS tapes. After quenching (a break-down of superconductivity), the full current could still be flowed in the leads for almost 10 seconds before reaching the defined hot spot temperature of 150 K. All of the above testifies to a robust design with a healthy operating margin in the superconductor as well as sufficient stabilization during a quench.

The turn-key control system delivered by the ITER Organization for the previous test campaign was also used in this test, including critical quench detection and interlock functions. ITER's Coil Power Supply Section also contributed by delivering a set of toroidal-field-type flexible copper busbars. ITER Organization representatives participated in the test, remotely as well as on site.

The next and final step of the HTS current lead qualification will be the testing of poloidal field/central solenoid prototype leads (which use a common design). The tests are scheduled for the end of 2015.