Fusion diagnostics heat up across the US

23 Oct 2015

-

Lynne Degitz, US ITER

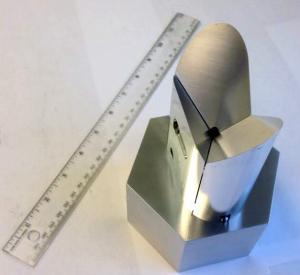

Six of seven US diagnostic systems are in the preliminary design phase with teams actively investigating physics and engineering issues through testing, prototype development and proof-of-principle activities. Pictured: a corner cube reflector prototype for the toroidal interferometer and polarimeter diagnostic. Photo: PPPL

The ITER tokamak will have over 60 diagnostic systems installed to enable plasma control, optimize plasma performance and support machine protection.

Two US laboratories, the Princeton Plasma Physics Laboratory (PPPL) and the Oak Ridge National Laboratory (ORNL) in collaboration with industry and universities, are developing the US contributions to ITER diagnostic systems. At this point, six of seven US diagnostic systems are in preliminary design with teams actively investigating physics and engineering issues through testing, prototype development and proof-of-principle activities.

"ITER diagnostics will use well-established techniques that are operational on tokamaks around the world. The challenge is designing systems that can withstand the harsh ITER operating environment," said US ITER diagnostics team leader Russ Feder of PPPL.

The first tokamak designed to sustain burning plasma, ITER will operate with pulse lengths up to an hour; diagnostic systems will potentially be exposed to high magnetic fields, neutron flux, and intense heat.

"ITER will also shake and move a lot. So we have to plan for vibrations and alignment challenges. This makes the physics and the engineering very interdependent," Feder said. "We have made major progress this year across six systems."

All of these diagnostic systems will feed information to ITER operators and scientists. One reason ITER has so many diagnostics is to provide redundant systems using different tools for measurement of similar plasma characteristics, confirming measurement accuracy.

Right now, teams are working on diagnostic systems across the US. Prototypes and testing are underway, with major recent progress occurring on the electron cyclotron emission diagnostic, the toroidal interferometer and polarimeter, and the upper infrared cameras.