Chinese Test Blanket System enters preliminary design phase

21 Mar 2016

-

ITER China

On 3-4 March 2016, the kick-off meeting for the Helium-Cooled Ceramic Breeder Test Blanket System (HCCB-TBS) brought together members of the Chinese Domestic Agency and experts from the Chinese institutes involved in the development program. The ITER Organization was represented by Luciano Giancarli, leader of the Tritium Breeding Blanket Systems Section, and by Jaap Van Der Laan, technical responsible officer of the HCCB-TBS TBM Arrangement.

The preliminary design phase for the Chinese Test Blanket System was launched on 3-4 March during a kick-off meeting held in Beijing. This important milestone followed the successful conclusion of the conceptual design phase in September 2015.

Tritium breeding self-sufficiency is compulsory in future large-scale fusion power plants. Scientists know that tritium can be produced within the tokamak when neutrons escaping the plasma interact with a specific element, lithium, contained in the blanket. Six technological solutions for a tritium breeding blanket—in the form of Test Blanket Modules (TBMs)—will be operated and tested for the first time in ITER. Combined with their ancillary systems (cooling, tritium extraction, measurements) they form the six Test Blanket Systems that are designed and procured by various Domestic Agencies.

Although the systems are all based on the principle of interaction between fusion neutrons and lithium, each one is unique in its architecture, its structural materials, its cooling system, the form of its lithium (solid or liquid), and the manner in which the tritium will be extracted. The Chinese concept—called the Helium-Cooled Ceramic Breeder Test Blanket System (HCCB-TBS)—is the first Test Blanket System to enter its preliminary design phase.

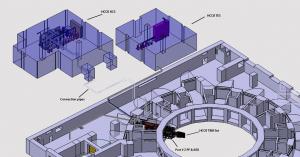

Test Blanket Modules like the HCCB TBM set will be integrated into port cells in order to have a front-row seat in the vacuum vessel. Located a distance away from the front-facing sets are ancillary systems such as the helium cooling system (HCS), the tritium extraction system (TES) and measurement systems.

A detailed work plan was officially presented by the Chinese Test Blanket System team during the kick-off meeting, chaired by the Chinese TBM Leader Chuanhong Pan and held in presence of the head of the Chinese Domestic Agency, Luo Delong, of representatives of the ITER Organization, and of experts from the three main Chinese institutes involved in the Test Blanket System development program: the Southwestern Institute of Physics (SWIP, Chengdu), the Chinese Academy of Engineering Physics (CAEP, Chengdu) and the Institute of Nuclear Safety Energy Technology (INEST, Hefei).

The work plan details the preliminary and final design phases (and the necessary R&D) for the various sub-systems and components of the HCCB-TBS such as the helium-cooling system, the tritium extraction system, the tritium accountancy system, and instrumentation and control. Participants at the meeting also discussed the required studies concerning safety and integration, and the design of a number of components that will be common to the two systems located in the same ITER equatorial port: the Chinese HCCB-TBS and Test Blanket System procured by India (the Lithium-Lead Ceramic Breeder, or LLCB-TBS).

Everything is now in place for the preliminary and final design activities to be performed for the Chinese Test Blanket System.