Winding completed on first central solenoid module

11 Apr 2016

-

US ITER

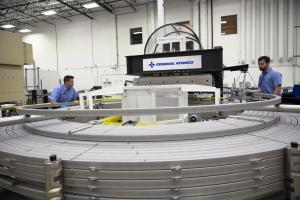

The final turns of the first central solenoid module on the winding table at General Atomics. Photo: GA

The US Domestic Agency and vendor General Atomics completed a major milestone on 6 April by winding the first module for the ITER central solenoid. The feat was accomplished at the General Atomics Magnet Development Facility in Poway, California.

Each central solenoid module is fabricated from approximately 6,000 metres of niobium-tin (Nb3Sn) conductor, supplied by Japan in seven spools. The central solenoid, a giant electromagnet considered the "heartbeat of ITER," will consist of six stacked modules surrounded by a support structure. When assembled, the entire 13 Tesla central solenoid and associated structures will be 13 metres tall and weigh 1,000 metric tons.

Conductor from six spools is wound to form six separate hexapancakes (6 layers) containing 14 turns. The seventh spool is wound to form a quadpancake (4 layers) containing 14 turns.

After winding, the completed hexapancakes and quadpancake will be stacked and joined prior to heat treatment, insulation, vacuum pressure impregnation, and final testing.