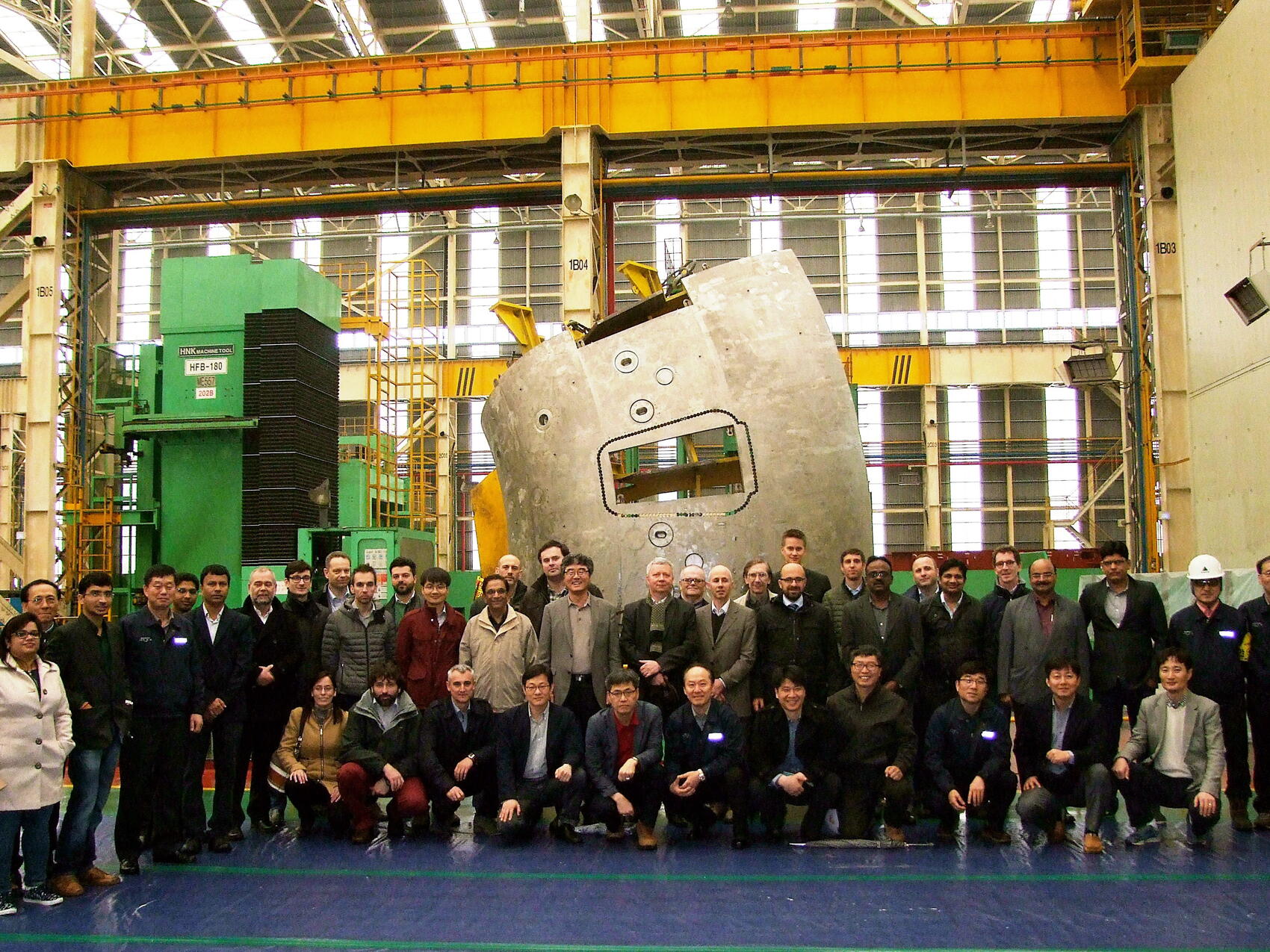

Vacuum Vessel Project Team meets in Korea

24 Apr 2016

-

ITER Korea

In early April, more than 50 experts met in Korea to discuss the fabrication of the ITER vacuum vessel, a technically challenging procurement that involves four ITER Domestic Agencies, the ITER Central Team and a large number of industrial contractors.

A penetration for in-vessel viewing and divertor cooling pipes at Hyundai Heavy Industries, in Ulsan. From left to right: ITER Vacuum Vessel and Thermal Shield Section Alex Martin, Yuri Utin and Chang-Ho Choi; Emmanuel Verdesio, Project Manager at AMW.

In 2015, representatives from all involved parties were reunited in the Vacuum Vessel Project Team, created by the ITER Executive Project Board to promote synergies, the sharing of experience, and the rapid resolution of fabrication issues for the vacuum vessel sectors, ports and in-wall shielding.

The vacuum vessel is a double-walled, hermetically sealed stainless steel vessel that houses the fusion reaction and acts as a first safety containment barrier. In the space between the double walls, steel in-wall shielding blocks will provide protection from neutron radiation for components situated outside of the vessel; in addition, cooling water will circulate to remove the heat generated during operation. Openings, or ports, in the vacuum vessel will provide access for remote handling operations, diagnostics, heating, and vacuum systems.

At the Project Team meeting held from 4 to 7 April at the National Fusion Research Institute and Hyundai Heavy Industry, members of the ITER Organization, the Domestic Agencies of Europe, India, Korea and Russia, and contractors AMW (Ansaldo Nucleare S.p.A, Mangiarotti S.p.A and Walter Tosto S.p.A.), Avasarala Technologies Ltd, Hyundai Heavy Industry, MDT (MAN Diesel & Turbo SE) and ENSA discussed manufacturing challenges—including complex interfaces, instrumentation, tolerances and technologies—and opportunities for simplification and improvement.

Already, collaboration within the Project Team has led to a marked acceleration in document review and approval time, the establishment of a baseline schedule for all procuring Domestic Agencies for monitoring purposes, and the much-improved resolution of interface issues. All participants to the April meeting agreed to keep on in this spirit.

View photo gallery below.