Designing modular tools for in-vessel assembly

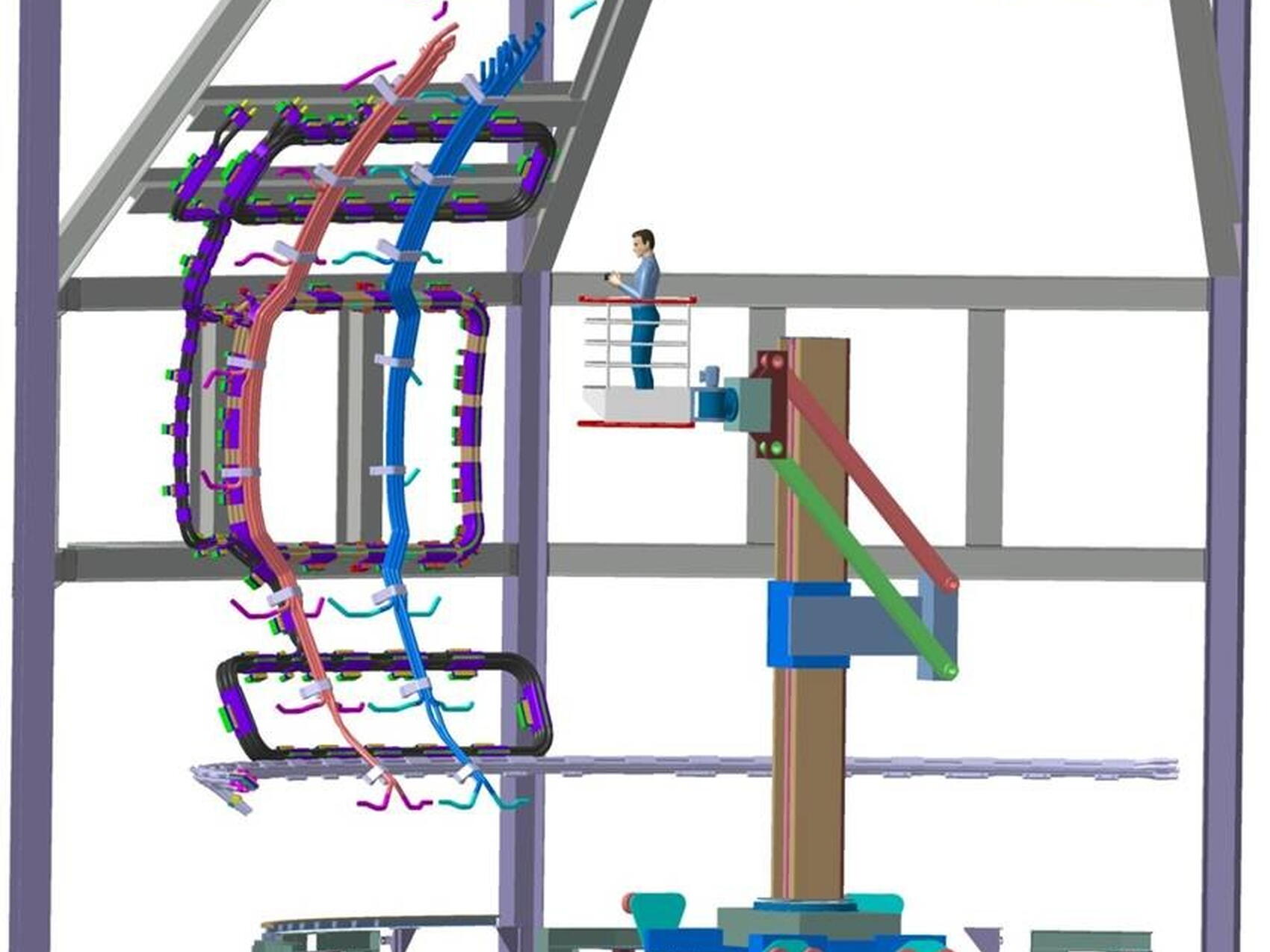

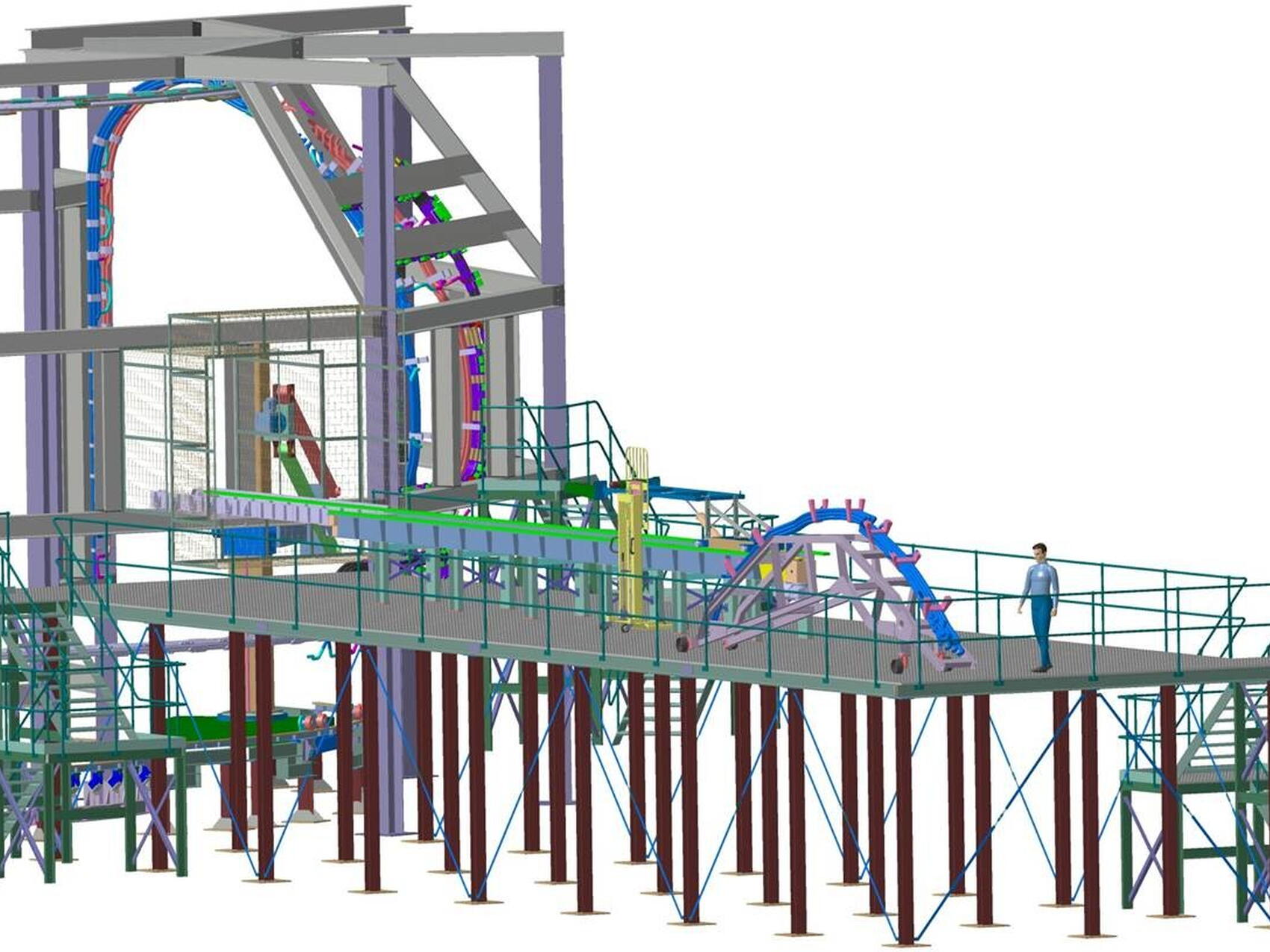

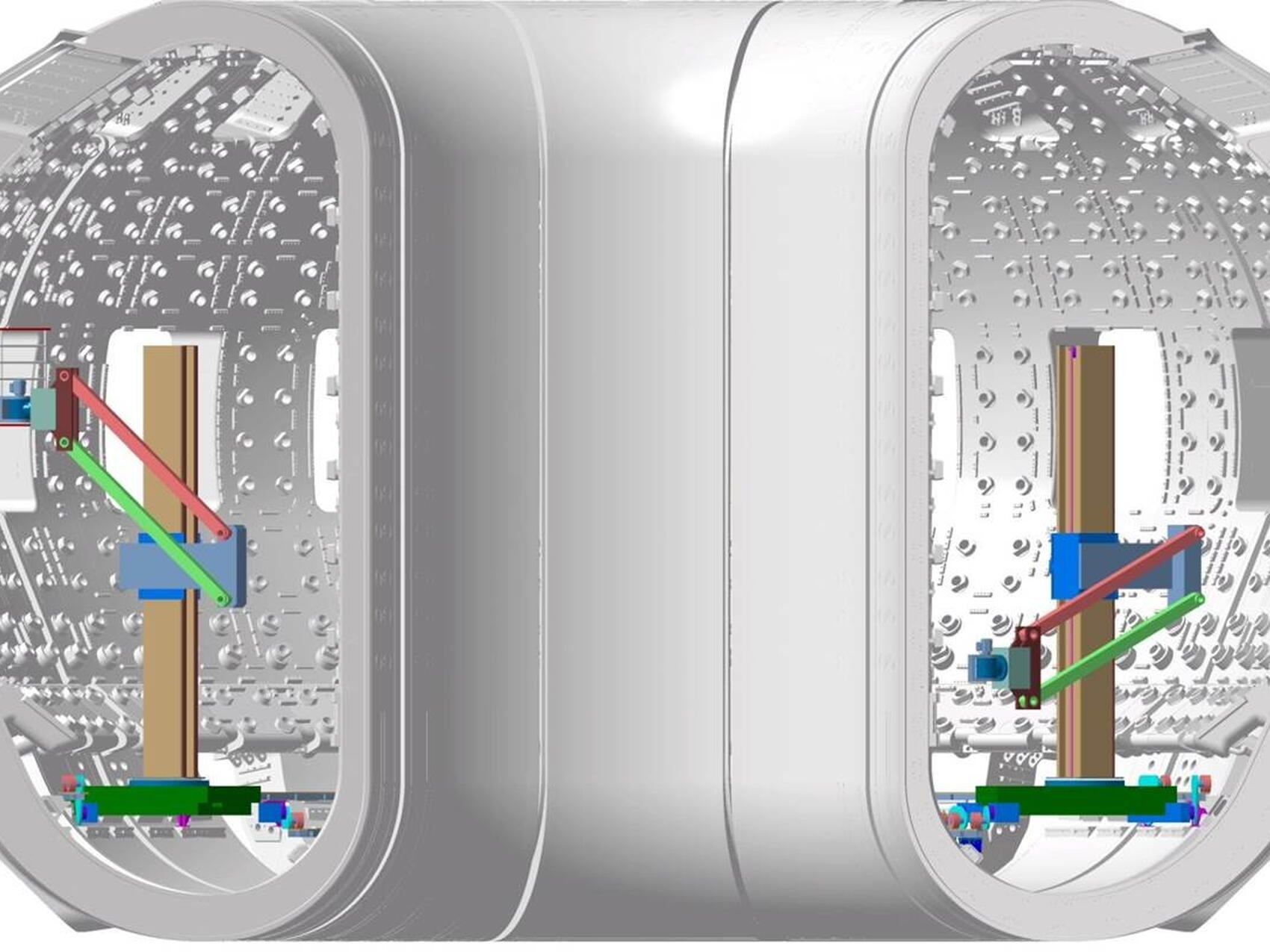

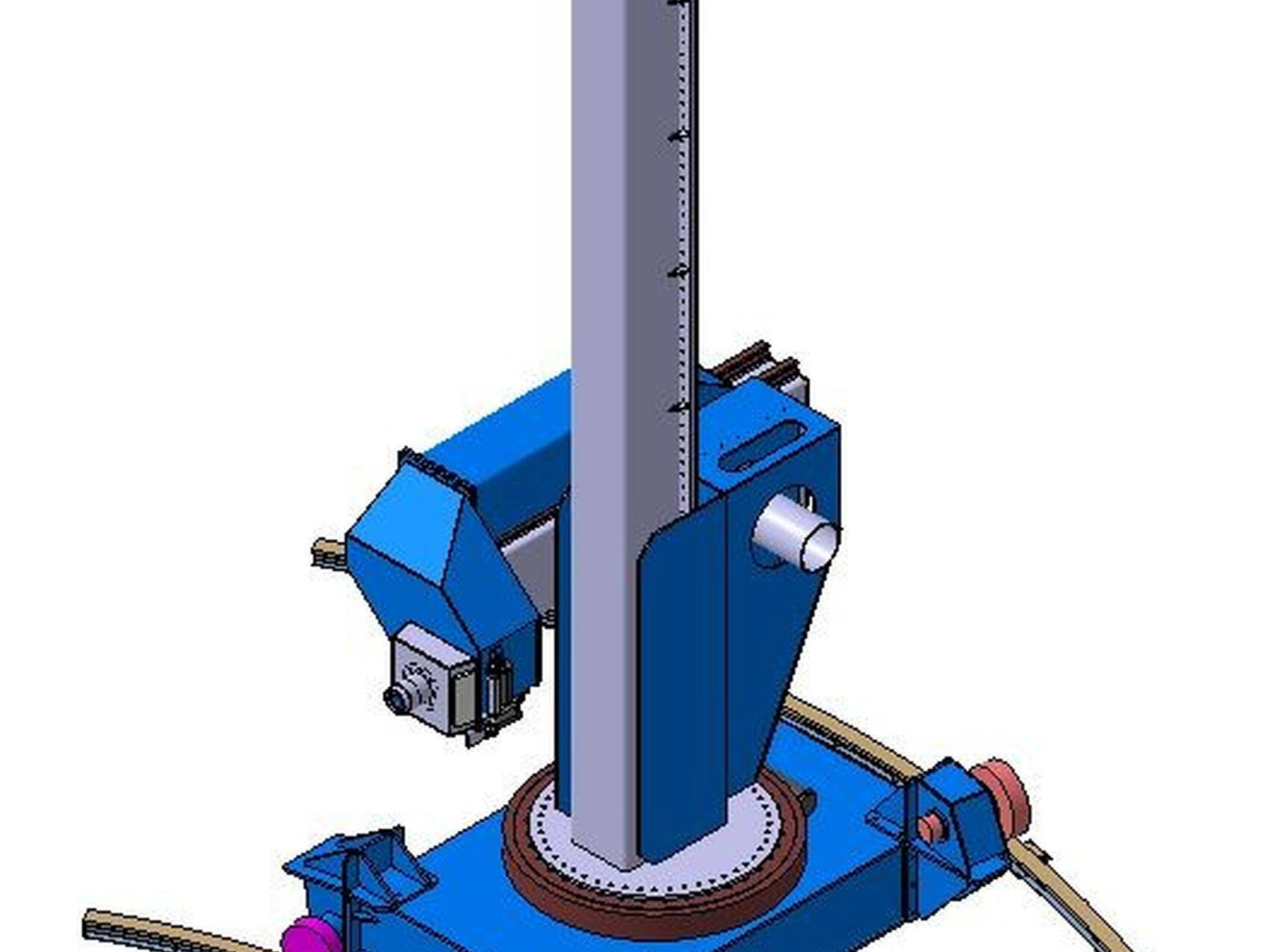

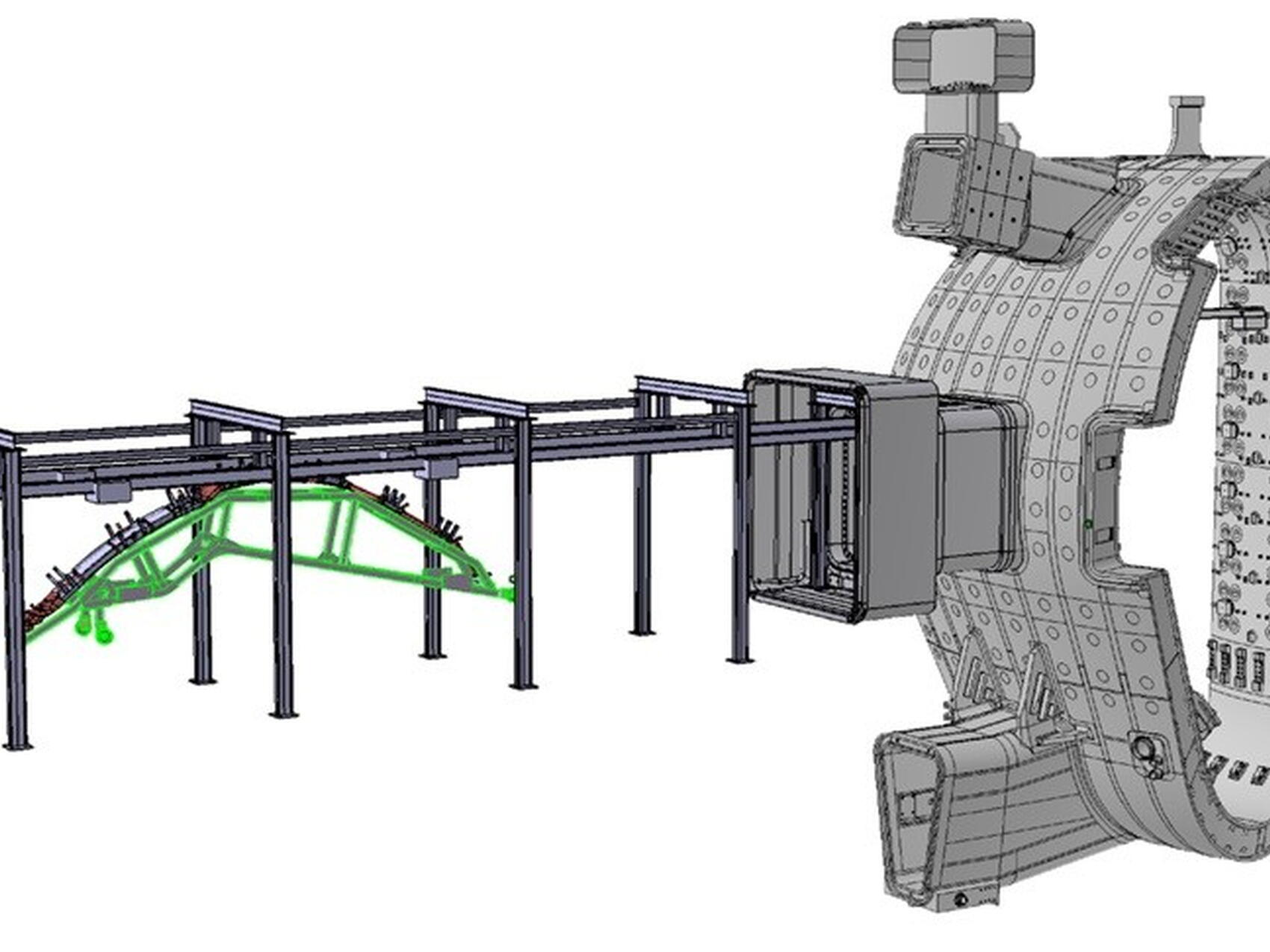

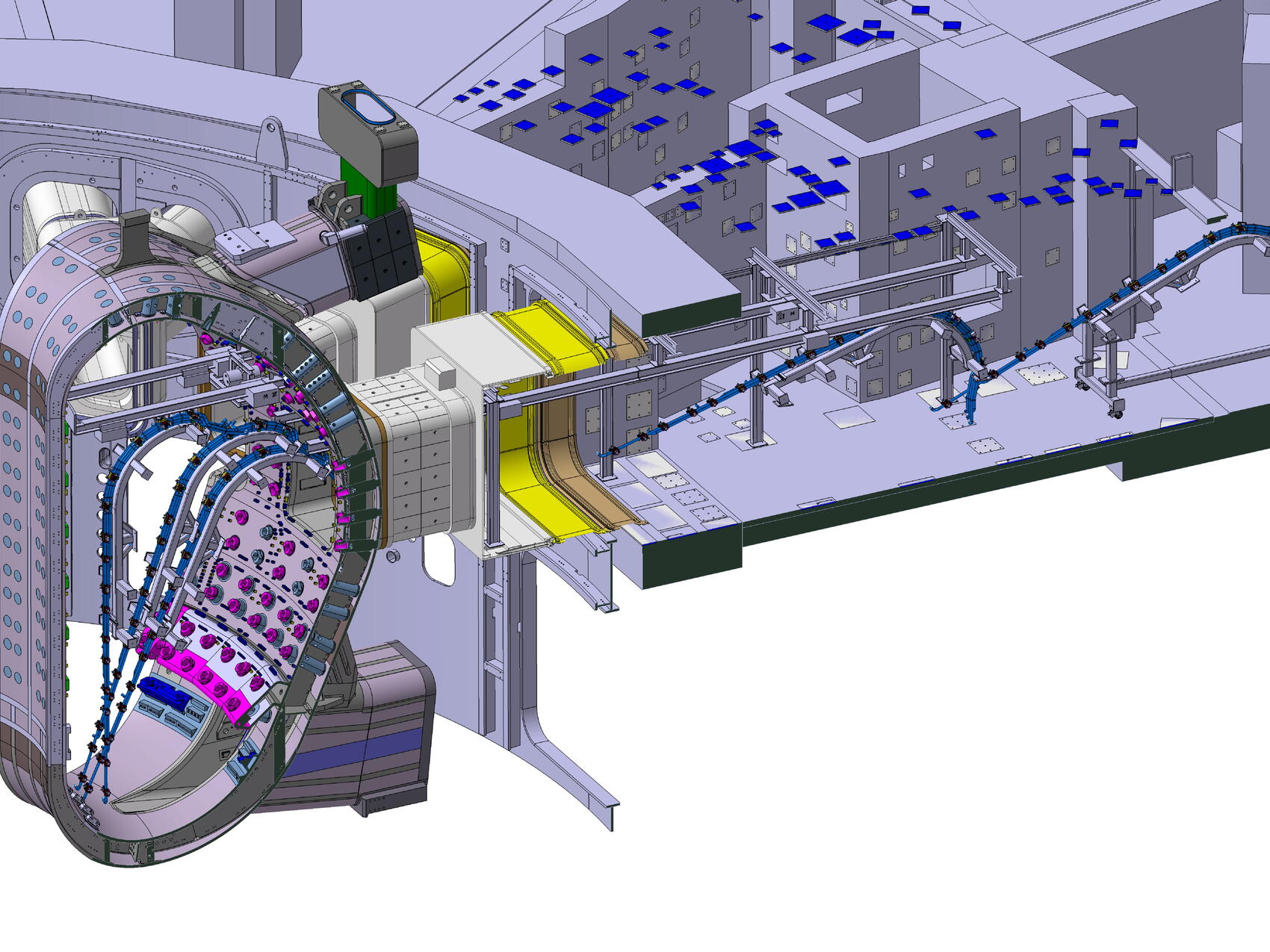

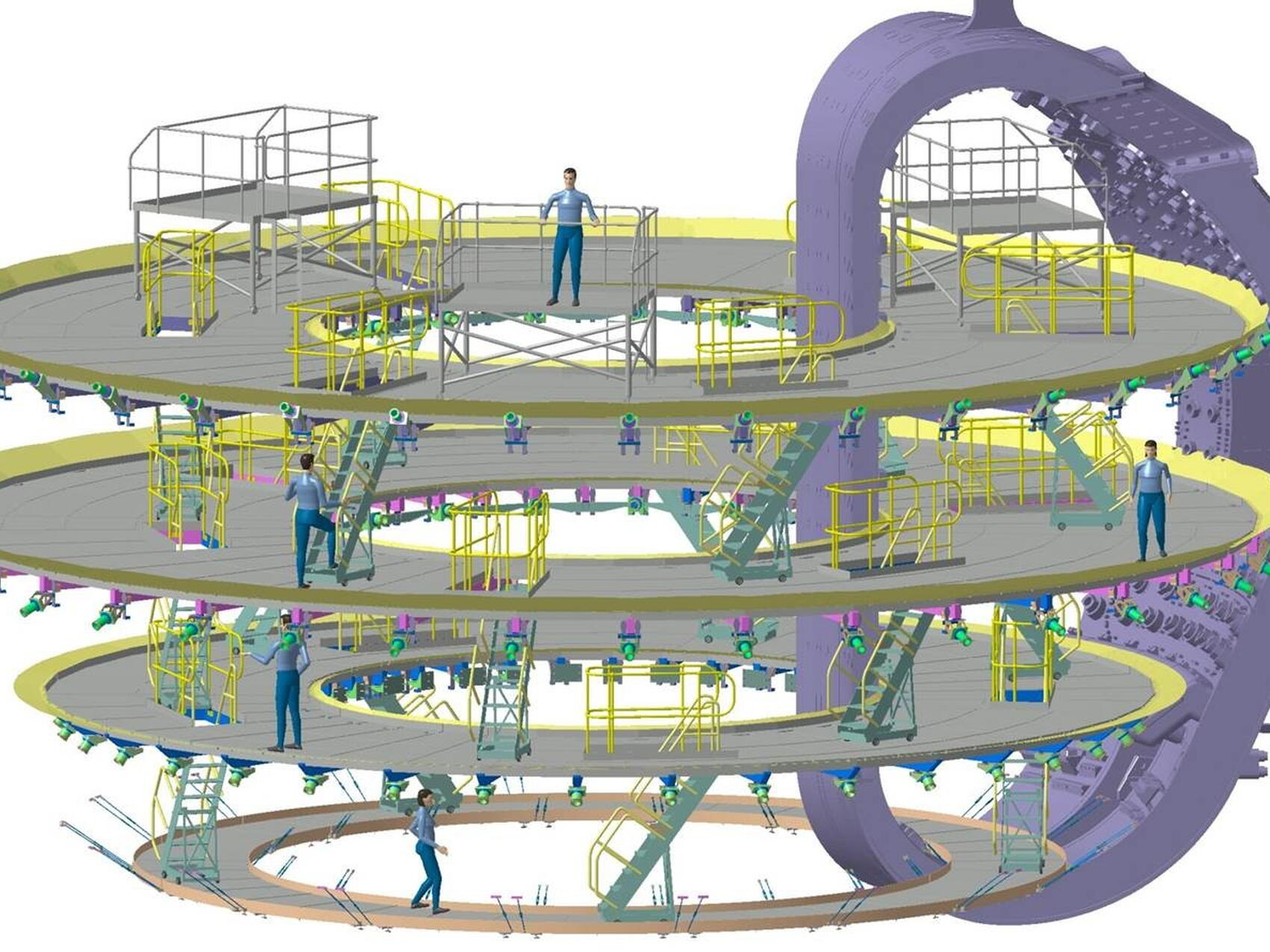

In order to carry out the installation of the ITER in-vessel components—such as the diagnostic looms, in-vessel coils, blanket shield blocks and first-wall panels—the ITER Organization will require a set of specifically engineered tools.

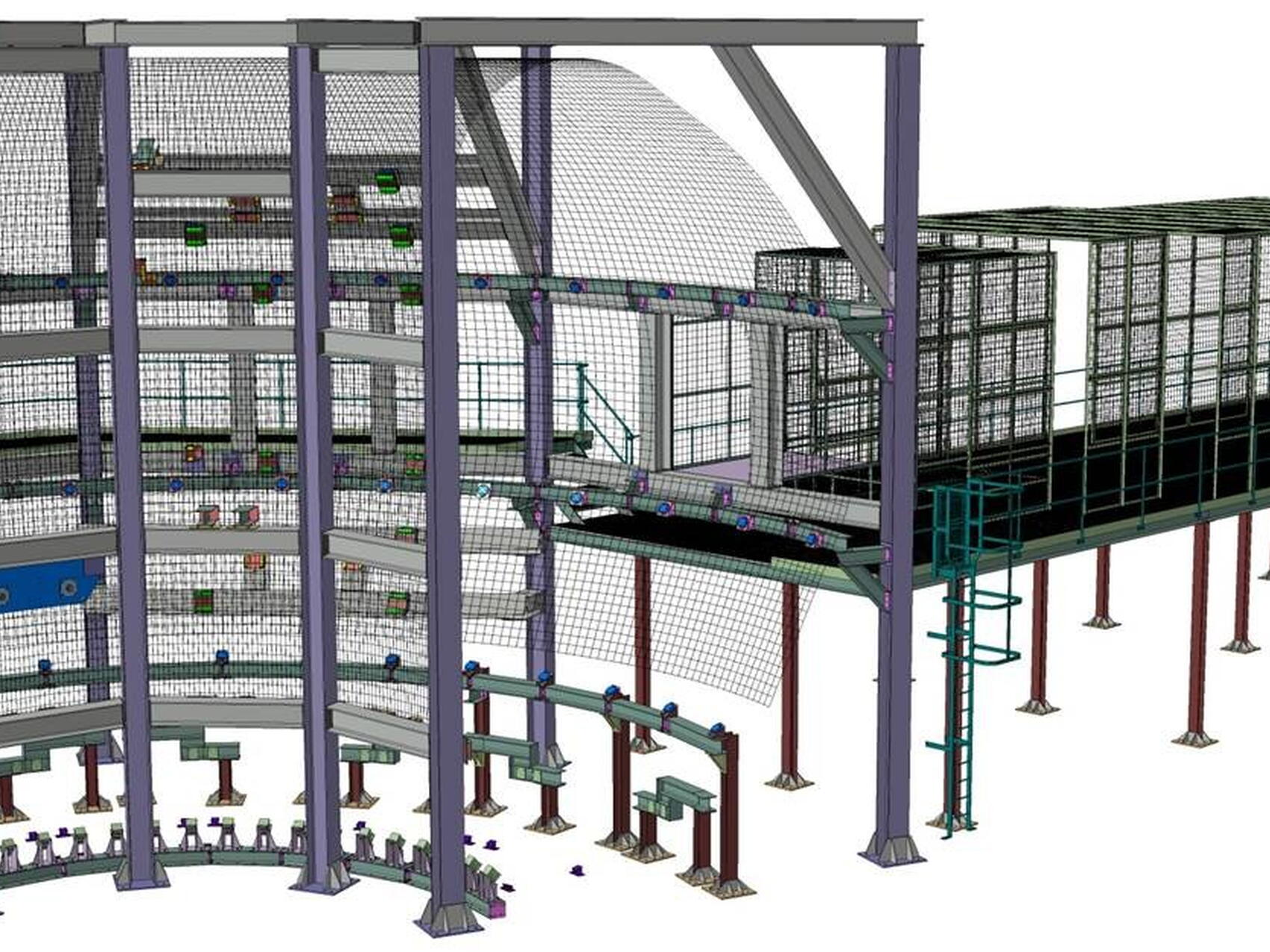

These tools will have to operate in limited space, respect challenging cleanliness specifications that restrict the type of lubricant or paint that can be used, and be capable of holding and positioning loads of around 5 tonnes with high accuracy. They will also have to be conceived in a modular fashion, to be assembled or dis-assembled as needed in the staging area.

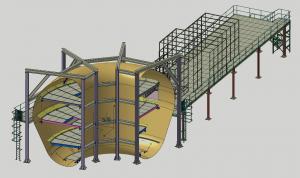

In December 2015, the ITER Organization signed a contract with CNIM Industrial Systems (Toulon, France) for the engineering design, manufacture and testing of the mechanical handling equipment as well as the platform-type staging required for access within the vessel. Contract scope also includes a trial and test facility that will serve to qualify the tools and to train future operators.

See the gallery below for a description for some of the principal in-vessel assembly tools.