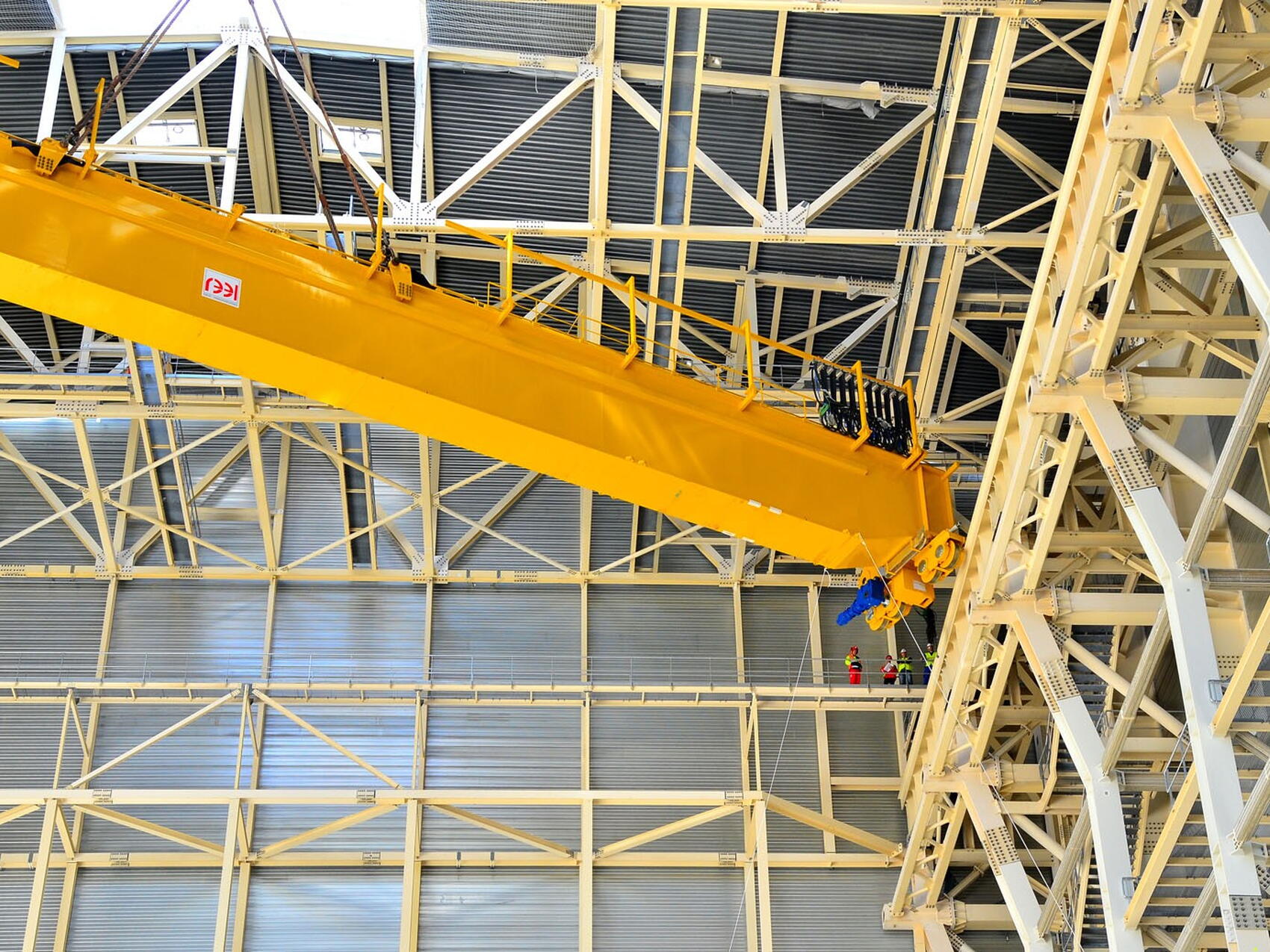

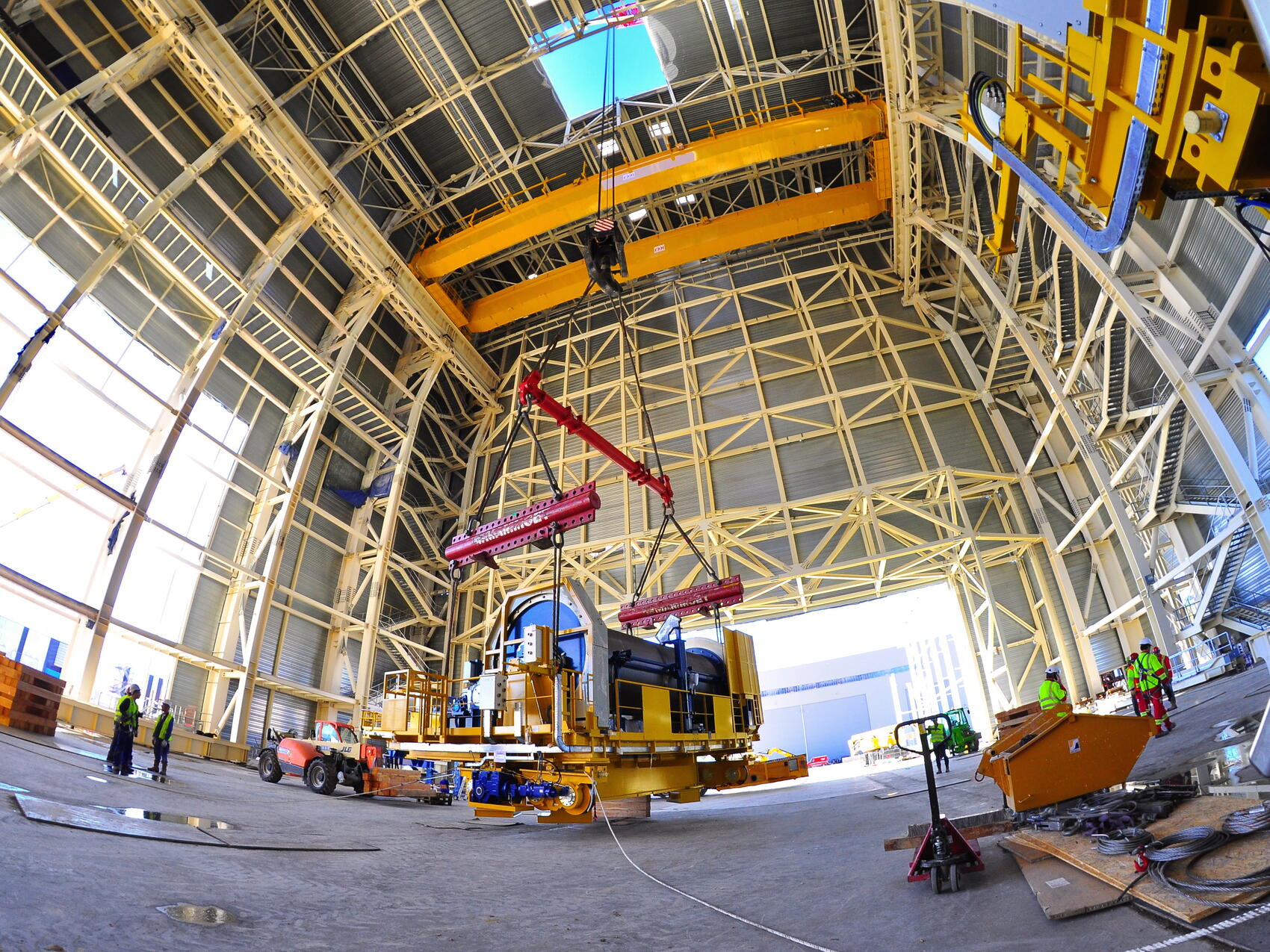

In order to lift the four girders and their corresponding trolleys into position 43 metres above the Assembly Hall basemat, the crawler crane was positioned outside the building. Its boom, high above the building, held a man-sized hook that passed through an opening in the roof and reached down to the waiting components.

Below, workers were busy adjusting cables, slings, braces and shackles in order to perfectly balance the first load to be lifted—one of the four girders, now fully

equipped with 30 tonnes of gear motors, wheels, braces, and electrical equipment and weighing 186 tonnes.

Despite the spectacular setting and the size of the components, the professionals appeared unfazed. "It's a standard operation," says Roberto Lanza of the ITER Building & Civil Works Section. "We'll first lift then slightly tilt each girder in order to align it with the rails above."

The operation is a mix of brute force, high technology and worker know-how. Connected by radio to the lifting supervisor, the crane operator sitting in his cabin outside the building slowly lifts the load. Surveyors direct their laser beams to ensure that everything is proceeding nominally, and men on the ground and up in the rafters use ropes to adjust the component's position.

As with all things ITER, tolerances are stringent. "The final adjustment must be ... and will be ... perfect," says Roberto.

Two of the four girders are now in place as well as one of the four 100-tonne trolleys. Lift operations will continue and by the end of this week the Assembly Hall will be fitted out with one of the most spectacular tools required for the assembly of the machine.