And now the "finishing" touch

27 Jun 2016

The main elements of the 1,500-tonne double overhead bridge crane—four girders and their corresponding trolleys—are now in place in the Assembly Hall. The big red crawler crane has been dismantled and is on its way to Sweden, where a 330-tonne "sphere" for liquid gas storage is waiting for a lift.

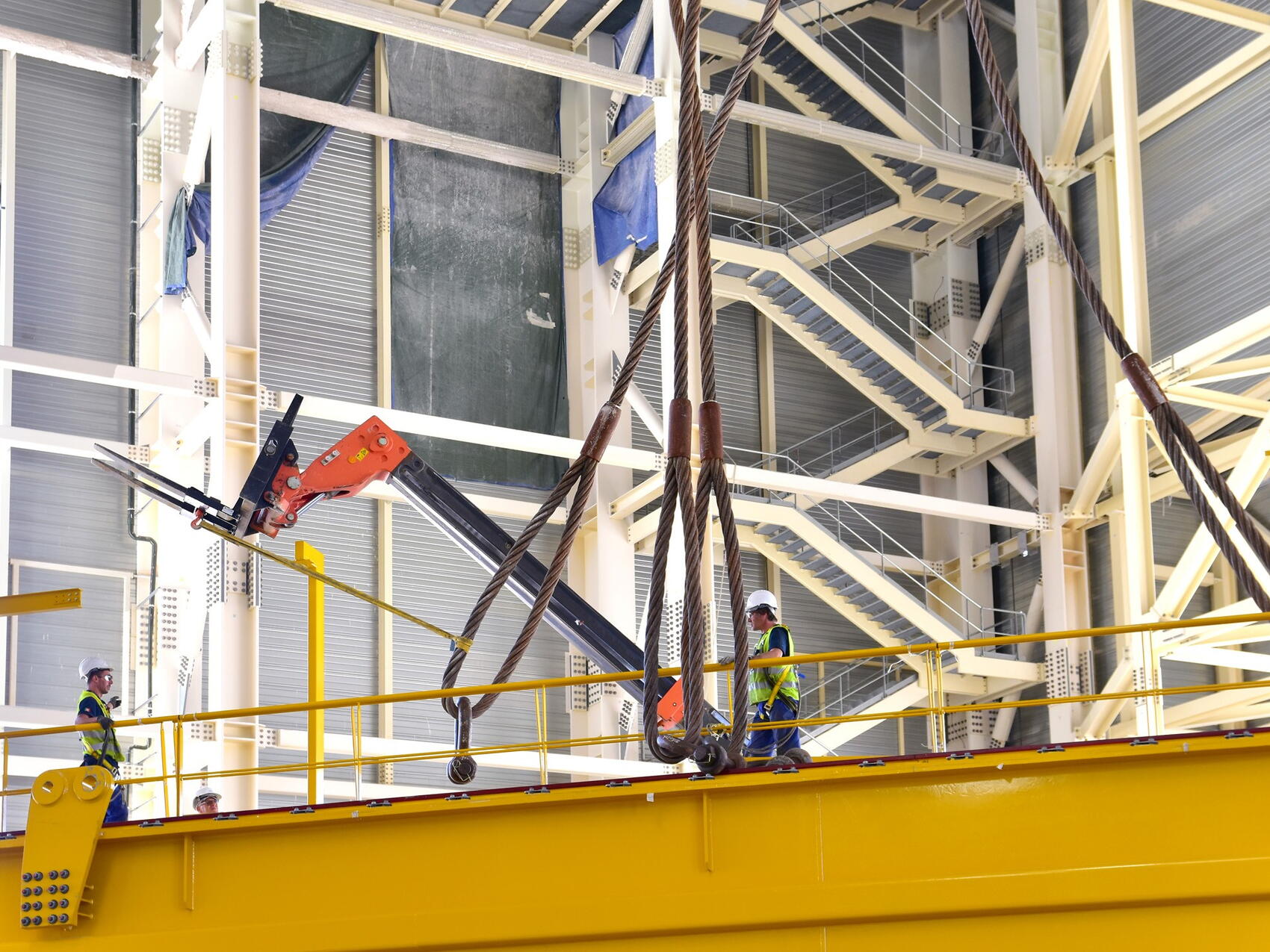

The most spectacular part of the operation is over. However, a considerable amount of work remains to be done, most of it at height, to finalize cabling connections, platform and walkway fittings, and the like--the "finishing" activities of the bridge crane installation.

By late September or early October, the two auxiliary cranes, each with a lifting capacity of 50 metric tonnes, will be delivered and installed. This time, there will be no need for a monster crawler crane operating from outside the building ...

Preliminary testing and commissioning are scheduled to begin in January/February 2017 for the large crane, and a few months later for the smaller one.