Bearing extreme forces

Tremendous forces will be exerted on the ITER machine when plasmas begin pulsating inside the vacuum vessel. As a consequence, the machine's support system needs to be both extremely robust, with a strong connection to the Tokamak Complex basemat, and yet also accommodating to the wobbling, expansion and occasional displacement of 23,000 tonnes of mass (tokamak plus cryostat).

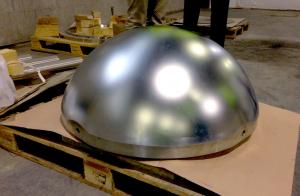

A massive pedestal—connected to walls that are radially anchored into the three-metre-thick bioshield—will allow for the even distribution of loads and efforts; a set of 18 spherical bearings acting like ball-and-socket joints will allow for the smooth transfer of horizontal, vertical and rotational forces, whether stemming from normal operations, a vertical displacement event or an earthquake.

In order to simulate the vertical compression forces that the bearings may be subject to a powerful hydraulic press, capable of delivering up to 7,000 tonnes (1) of vertical pressure, was purpose-built. Equipped with additional jacks, the press also simulates the cryostat's lateral and rotational loads.