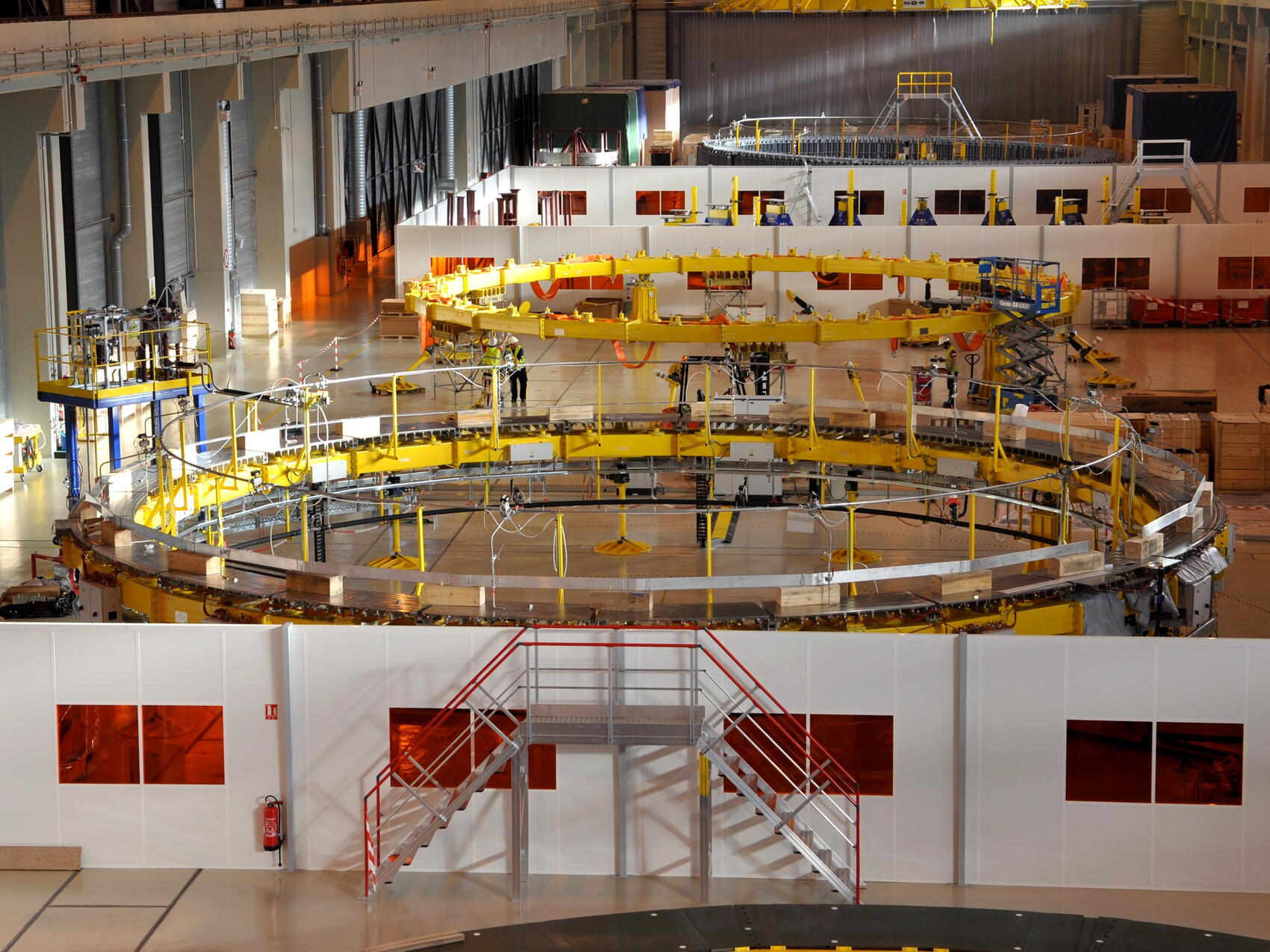

The making of a ring coil—a photo story

From one end to the other of the on-site manufacturing facility for poloidal field coils, the different production stations are now clearly delimited, with tooling in various stages of installation. In this 257-metre-long workshop, European contractors will carry out the winding, impregnation, and assembly phases for the four largest ring magnets, with diameters of 17 to 24 metres.