In 2012, a consortium formed by European firms SIMIC and CNIM (France) has been awarded the contract for 70 radial plates needed by Europe for the production of ten toroidal field coils. With the realization of its 35th radial plate, SIMIC has now completed its share. The last 9 x 13 metre plate, weighing almost 10 tonnes, will be sent on to the European winding facility in La Spezia, Italy, where toroidal field coil manufacturing is underway.

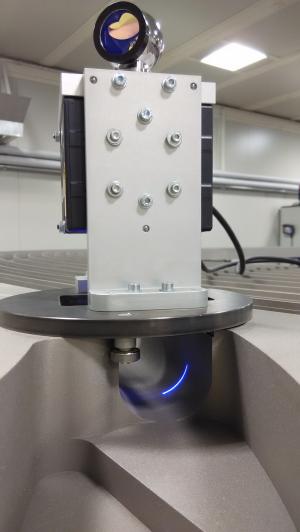

The role of the radial plate is to hold the wound conductor in place. Each toroidal field coil contains five regular radial plates (with 12 grooves per side) and two side radial plates (with respectively 9 and 3 groves on the two sides). The plates require high-precision manufacturing and strict dimensional control to reach the tight specified tolerances. At SIMIC, an Italian firm specialized in the engineering and manufacturing of large machined components, a team of 70 people has been working for four years.