10,000 tonnes of magnets to cool

17 Apr 2017

In ITER, huge volumes of liquid helium will be circulated throughout a complex, five-kilometre network of pipes, pumps and valves to keep the 10,000-tonne magnet system at superconducting temperature. Helium will also be required to provide cooling power to the thermal shields—which reduce the large temperature gradient between the superconducting magnets and the Tokamak environment—and the cryopumps, which use extreme cold to achieve high vacuum in the plasma chamber.

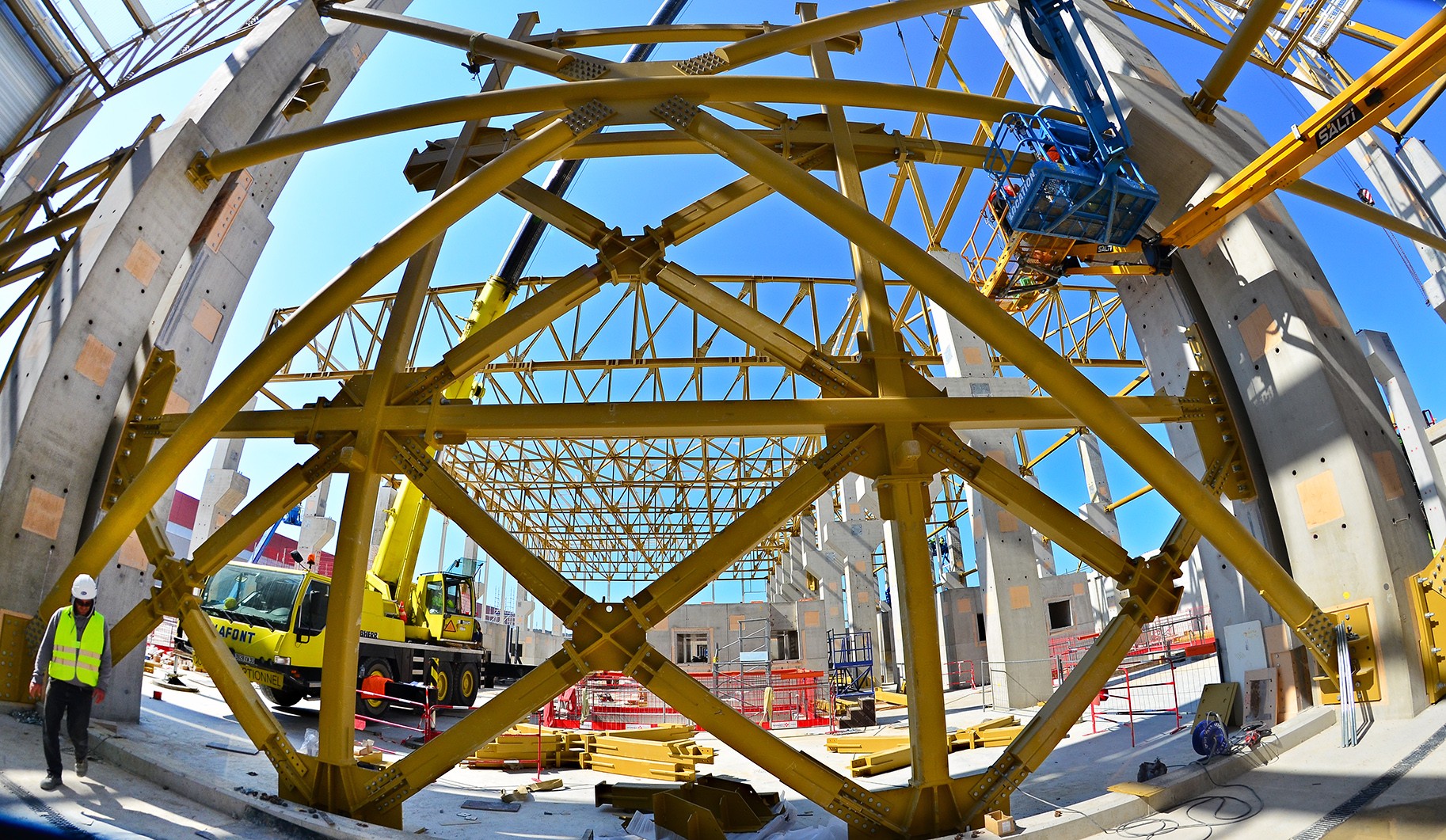

The cryoplant area stretches over 8,000-square-metre zone not far from the Tokamak Building. Part of the area is given over to the storage of helium and nitrogen in liquid and gaseous forms; the rest (5,400 m²) is for the Cold Box and Compressor buildings that will be joined under a single roof.

As a consequence, the ITER cryoplant will be the largest in the world. Nearly 25 tonnes of liquid helium at minus 269 °C will circulate in the ITER installation during operation.

Helium however is not the only ultra-cold fluid that the cryoplant will produce. Liquid nitrogen, at a temperature of minus 196 °C, will be used as a "pre-cooler" in the liquid helium plants.

Nitrogen, which accounts for approximately 78 percent of the air we breathe, will be extracted directly from the atmosphere in an on-site gaseous nitrogen generator with a production capacity of 50 tonnes per day, and then processed in two large liquid nitrogen plants.

The complexity of the cooling processes, along with the flux rate required for the cooling of magnets, cryopumps and thermal shield, has dictated the size and design of the cryoplant.

Construction is underway now on the buildings and technical areas of the cryoplant.

The images below show recent progress on site. Access for the first installation activities is expected in June.