Before transport to ITER, the plaque bearing the presidential signature was removed and placed in the company's museum. One does not take chances with non-standard elements in a component as complex as these huge refrigerators, designed to cool gaseous helium to the ultra-low temperature of 4.5 K (minus 269° C).

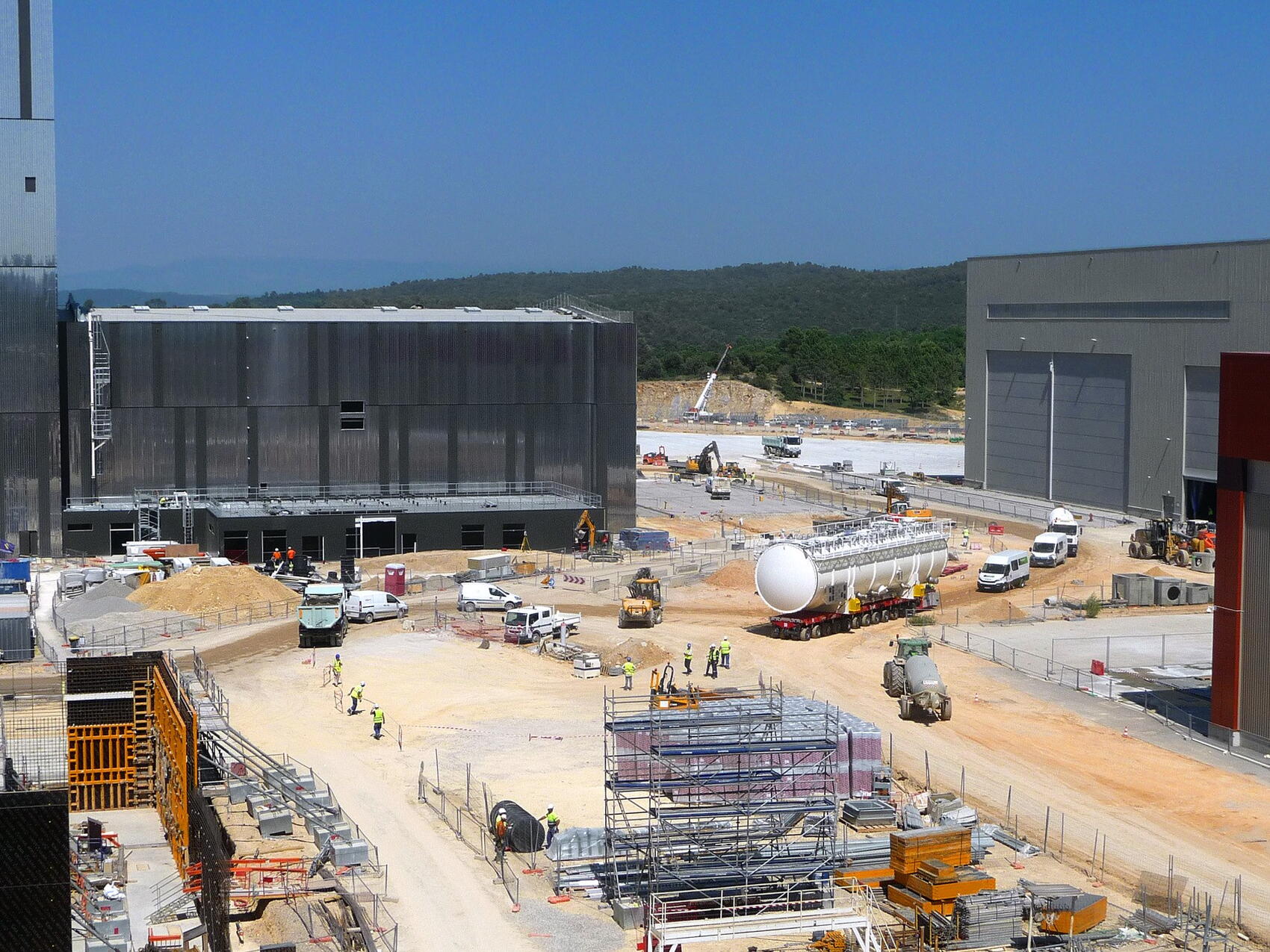

From the 8,000 square-metre cryoplant located at ITER (covered buildings plus exterior storage areas) helium and nitrogen will be produced at various temperatures and distributed to the "cold" clients of the machine; that is, the superconducting magnets, cryopumps and thermal shield that function at cryogenic temperatures.

The 21-metre cold boxes—each weighing about 137 tonnes with internal components—provide an insulated environment for components such as heat exchangers, cryogenic adsorbers, liquid helium and liquid nitrogen phase separators. Under

contract with the ITER Organization, Air Liquide is responsible for the design, manufacturing, installation and commissioning of the liquid helium plants. The vessels were manufactured by SIMIC (Italy) and transported to the Air Liquide factory in Sassenage, near Grenoble, France, where all internal components were integrated.

The installation of the first components in the ITER cryoplant represents the on-time achievement of an ITER Council milestone for project construction. With over 4,500 components in all, however, cryoplant installation work is far from complete. Upcoming milestones include the installation in the Compressor Building in of 18 motor-compressor skids, each weighing approximately 20 tonnes, which compress gaseous helium before it is cooled in the cold boxes through the expansion process. (Gases heat up when compressed and cool down when they expand.)

The ITER Cryogenic System Section is also expecting the delivery of a "test cryostat" from Air Liquide this week that will be used to verify the performance of the three cold boxes as part of site acceptance procedures that are stipulated in the procurement documents. With the capacity to simulate the "heat load" of the systems that the cryoplant will be called on to cool down, the test cryostat will be used to test each cold box separately, over a period of 18 months, before the three are tested together in final site acceptance tests.

See the gallery below for photos of cold box transport and installation.

The European Domestic Agency has also published a report on the many tanks that are ready for installation in the exterior storage area of the cryoplant.