It's all happening inside

17 Jul 2017

Since the giant poster was added to the Assembly Hall's completed exterior in June 2016 the building has looked from afar like a finished project. But inside, teams have been advancing on finishing works—installing plasterboard, lighting, fire protection, cable trays; jointing and painting; and creating stairwells and a lift. Most recently, a first coat of varnish was applied to the floor to limit dust, testing of the overhead cranes started, and a special zone was prepared for the building's first and most impressive assembly tools, the twin vacuum vessel sector sub-assembly tools. European contractors successfully achieved an ITER Council milestone in late June by making one part of the Assembly Hall "ready for equipment."

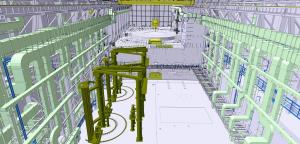

In the 60-metre-tall building for pre-assembly activities, workers go over the painted surface of the basemat. Later, when construction activities on the Tokamak Building are finalized, the temporary wall seen at the end of the building will come down and the cranes will operate along a 170-metre crane bay. The double building will operated as a clean space during the assembly of the machine.

These anchor bolts are ready to receive the wing rails and columns of the vacuum vessel sector sub-assembly tools. On this reinforced area of the Assembly Building basemat, contractors will begin tool installation activities in August. By the end of the year, the first tool should be standing 22 metres tall.

In this image, the Tokamak Building has been finalized and the temporary wall that closes it off from the Assembly Building has come down. We see the full crane bay, with the machine assembly area in the background. Also evident, the semicircular "footprint" of the sector sub-assembly tools, which is already traced out on the reinforced basemat of the Assemly Hall (see second photo).