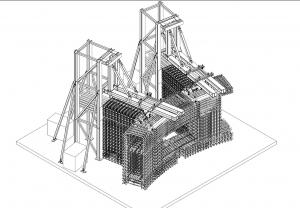

Crown mockup

Answering questions 3D models can't

9 Oct 2017

-

R.A.

In some areas of the Tokamak Building the steel reinforcement is so dense and the arrangement of the bars so complex, that even the most detailed 3D models are not sufficient to demonstrate full constructability.

In order to demonstrate the full constructability of the massive structure (the "crown") that will support the machine, a 1:1 mockup is being erected on the ITER platform.

A 3D model certainly describes the position, dimension, relative angle and curvature of every steel bar needed in a construction with utmost precision. But there are important questions that a model cannot answer. What are the most efficient rebar installation sequences? Will there be enough moving room for the workers to insert the bars, manoeuver them into the right position, and tie the stirrups?

(¹) Once the process is complete, the pipes will be filled with grouting.

And the 3D model will provide no information on how the concrete will settle into the steel lattice.

This is why when things get particularly challenging, constructors choose to try their hand on a mockup. "A 1:1-size mockup provides the ultimate demonstration of constructability," explain Laurent Patisson and Armand Gjoklaj, from ITER's Civil Structural Architecture team. "It's all about learning and fine-tuning procedures."

Mockups for ITER construction are like everything at ITER—large and complex. Since work began on Tokamak Complex foundations seven years ago, mockups have been erected on three occasions: in 2013 for the building's supporting slab (B2); in 2015 for the bioshield; and now one for the "crown" that will support the combined mass (23,000 tonnes) of the machine's cryostat, vacuum vessel, magnet system and thermal shield. (Compared to the 2015 mockup, the present one includes more elements of the crown such as toroidal beams and circular wall.)

Construction of the latest mockup—which has a footprint of 50 m² and a height of 3 metres—began three months ago. Reproducing a 40-degree section of the crown, the mockup's dense lattice is created from 50-millimetre-thick steel bars, a breadth not encountered anywhere else in the Tokamak Complex.

The mockup will enable the Buildings Infrastructure and Power Supplies (BIPS) Project Team to demonstrate not only the feasibility of the rebar installation but also the penetration and placement of the concrete into the steel lattice.

The concrete's formulation for the crown ("C90") is also unique in the Tokamak Complex. It combines fluidity when poured and extreme "hardness" when settled.

Inside the mockup, the temperature during the hardening process will be regulated and homogenized by cooling water circulating inside of thin pipes¹ and monitored by sensors distributed throughout the structure.

In preparing for the actual construction of the crown, the BIPS Project Team feels confident but has decided to take no chances—the 1:1 mockup must deliver the final demonstration that, yes, it can be done.

(¹) Once the process is complete, the pipes will be filled with grouting.