Last cryogenic tanks from Europe

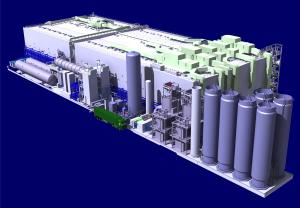

Eleven storage tanks have been delivered by the European Domestic Agency in the past year for the ITER cryoplant, including two this past week.

The fabrication of the tanks for the ITER cryoplant was undertaken by European contractor Air Liquide and its subcontractors in such faraway locations as Sweden, the Czech Republic, China and Turkey, while logistics were handled by ITER's global logistics provider, DAHER.

Ten other tanks—six gaseous helium (GHe) tanks, one liquid nitrogen tank (LN2), one gaseous nitrogen tank (GN2), and two quench tanks for the storage of helium expelled from the ITER magnets in the case of a quench—are also needed as part of the cryoplant infrastructure.

Read the full report on the European Domestic Agency website.