Worksite progress

Spot the differences

22 Jan 2018

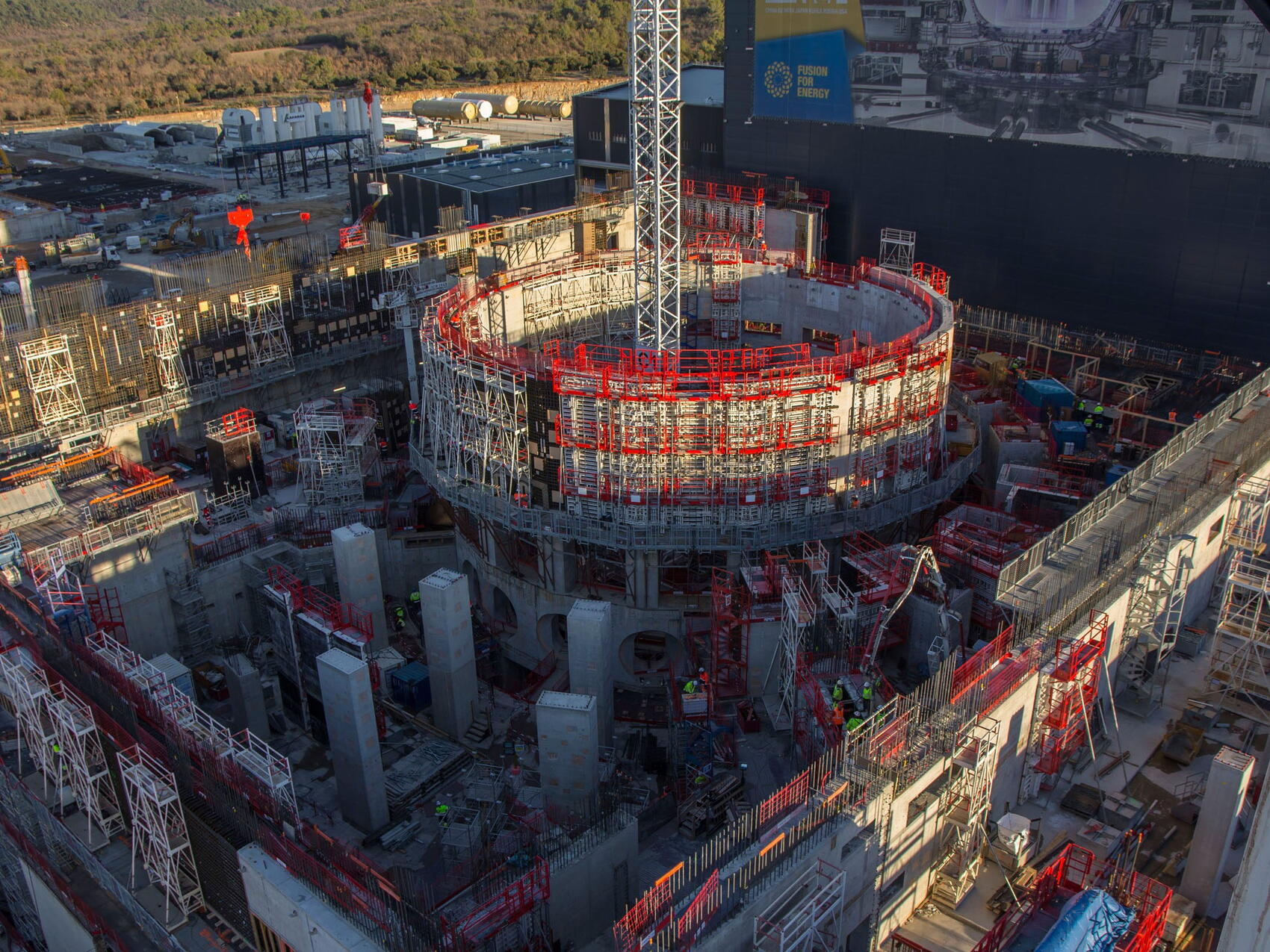

Let's play the "spot the differences" game between these two general views of the ITER site, one taken last Thursday 18 January, the other three months ago on 11 October.

At first view nothing stands out as being dramatically different. But on closer inspection, most everything has changed.

In the Tokamak Complex to the left, the bioshield has come full circle, at least visually. Only 30 percent of the last level (L4) remains to be poured, and this work should be completed in the coming weeks.

Just outside of the bioshield, in the area of the Tokamak Building that will host neutral beam injection equipment, many new columns are in place. These strong pillars will support the next-level floor slab (L3).

Running vertically down the centre of the photograph, columns and formwork are in place for what will be the roof (L4) of the Diagnostics Building.

As for the plant buildings on the right, the changes are mostly taking place on the inside with the installation of equipment and services. In the months to come, however, we can expect to see the first large tanks going up along the cryoplant (second building from the top)—11 will be installed in all.

More details in the photo gallery below.