Cryostat Workshop

Lower cylinder and base take shape

5 Feb 2018

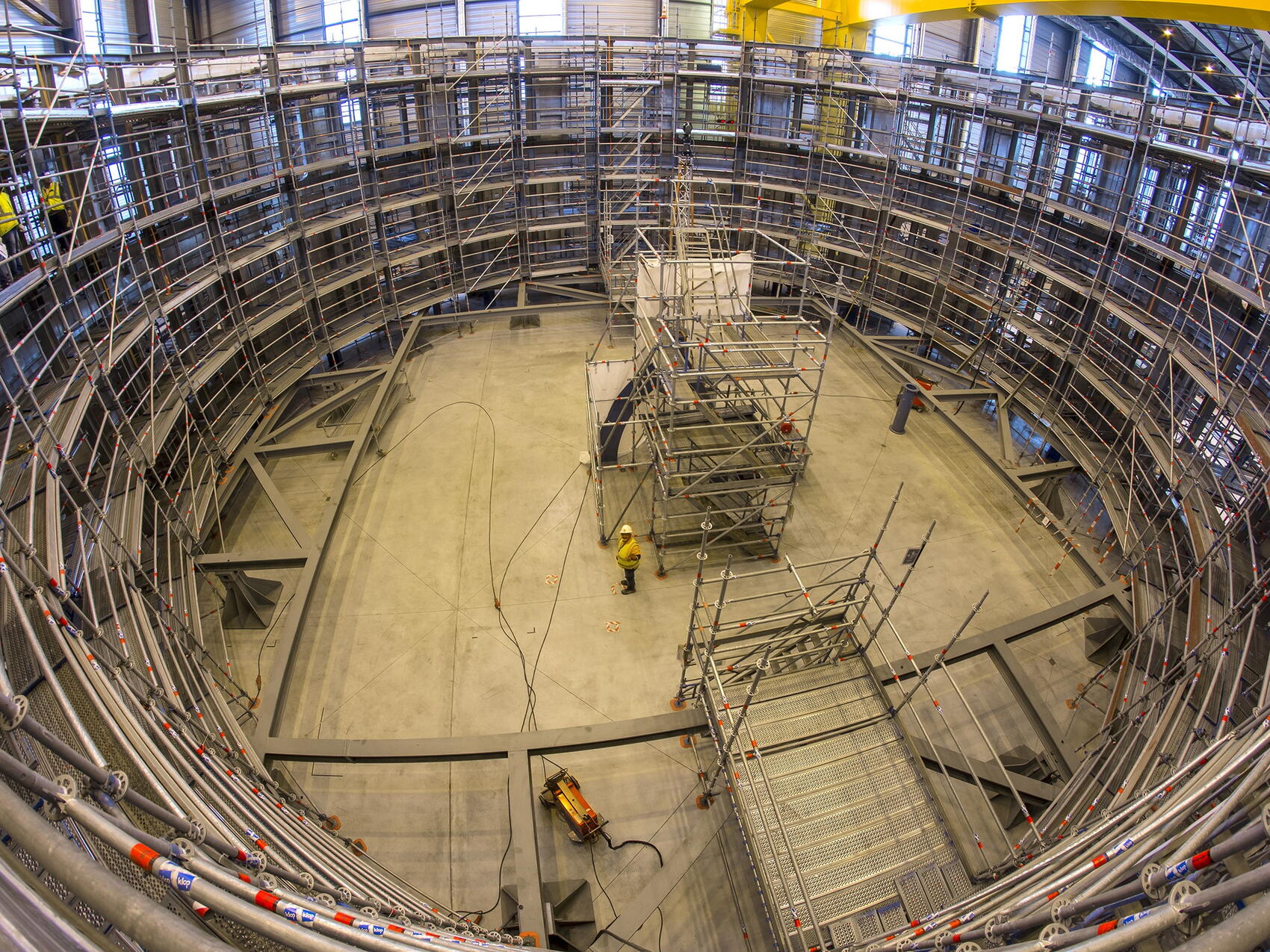

The lower cylinder of the ITER cryostat represents only one-third of the whole component's height. Still—it dwarfs the men standing nearby.

Nothing gives a better sense of the size of the ITER machine than the ongoing works in the Cryostat Workshop, where the the lower cylinder and base section of the cryostat are being assembled and welded under the responsibility of Indian contractor Larsen & Toubro.

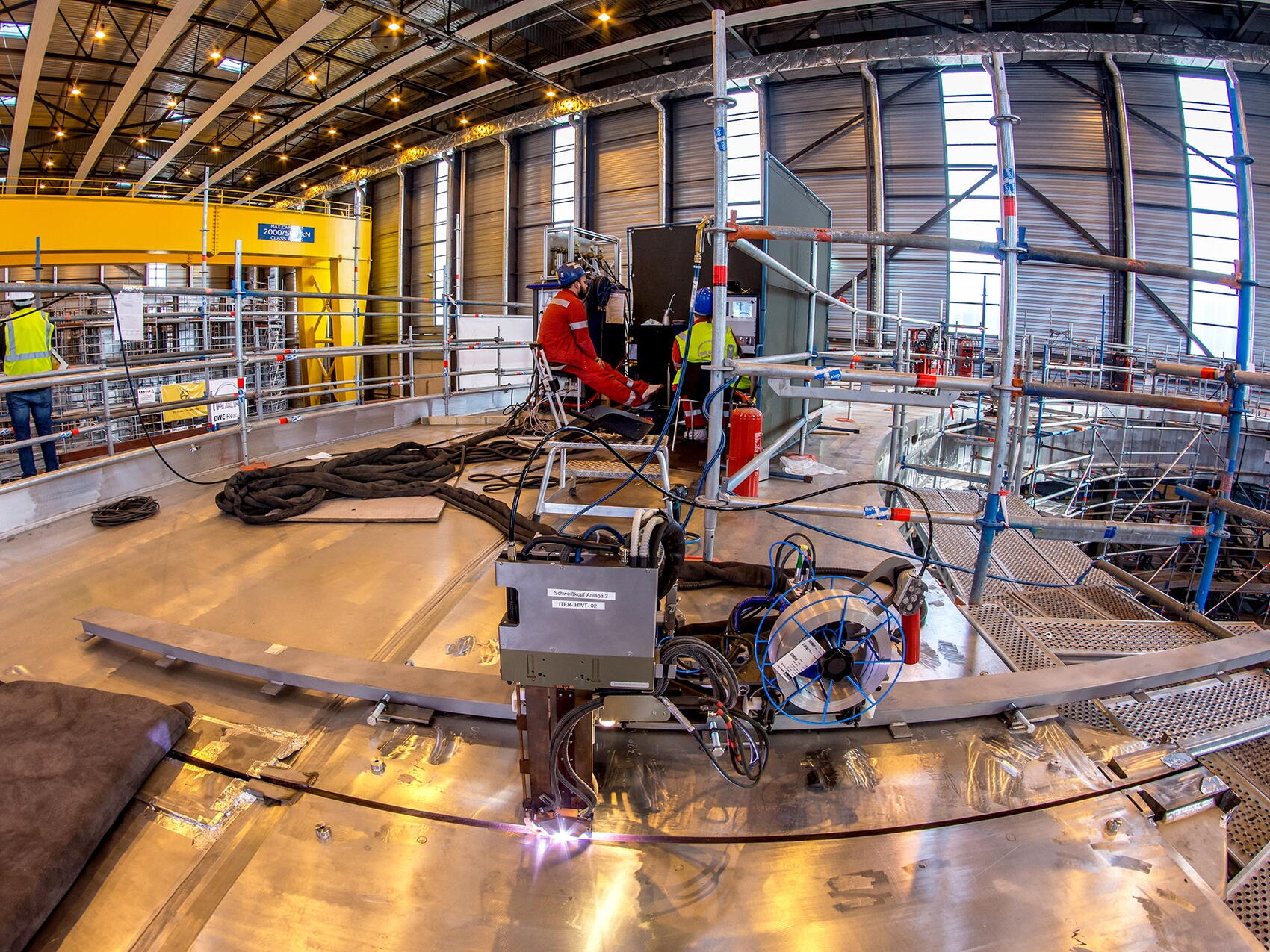

Both tiers of the cryostat lower cylinder are now in place, stacked one on top of the other. The lower tier is already fully welded, while the segments of the upper tier are being readied for welding operations.

At the other end of the football-field-size Cryostat Workshop, the base of the cryostat is progressively taking shape.

The base section—1,250 tonnes—is the single heaviest piece of the ITER machine. Its form can be compared to that of a deep soup plate, with a 20-metre-in-diameter base, vertical walls and a broad rim (1.30 metre wide and 30 metres in diameter).

The lower portion of this sub-component (equivalent to the bottom of the soup plate) has been finalized. All non-destructive examination tests on the welds were completed, as well as all dimensional/tolerance tests.

On the pedestal rim (the soup plate's rim) welding is now 50 percent complete. For the moment, the space between the two is empty—in other words, the plate has a bottom and a rim, but nothing connecting the two.

"By fitting what we call the 'main shell' only after the pedestal ring and the bottom of the base section are installed provides more flexibility for adjustments," explains ITER cryostat engineer Guillaume Vitupier.

Further explanation on the ongoing operations can be found in the gallery below.