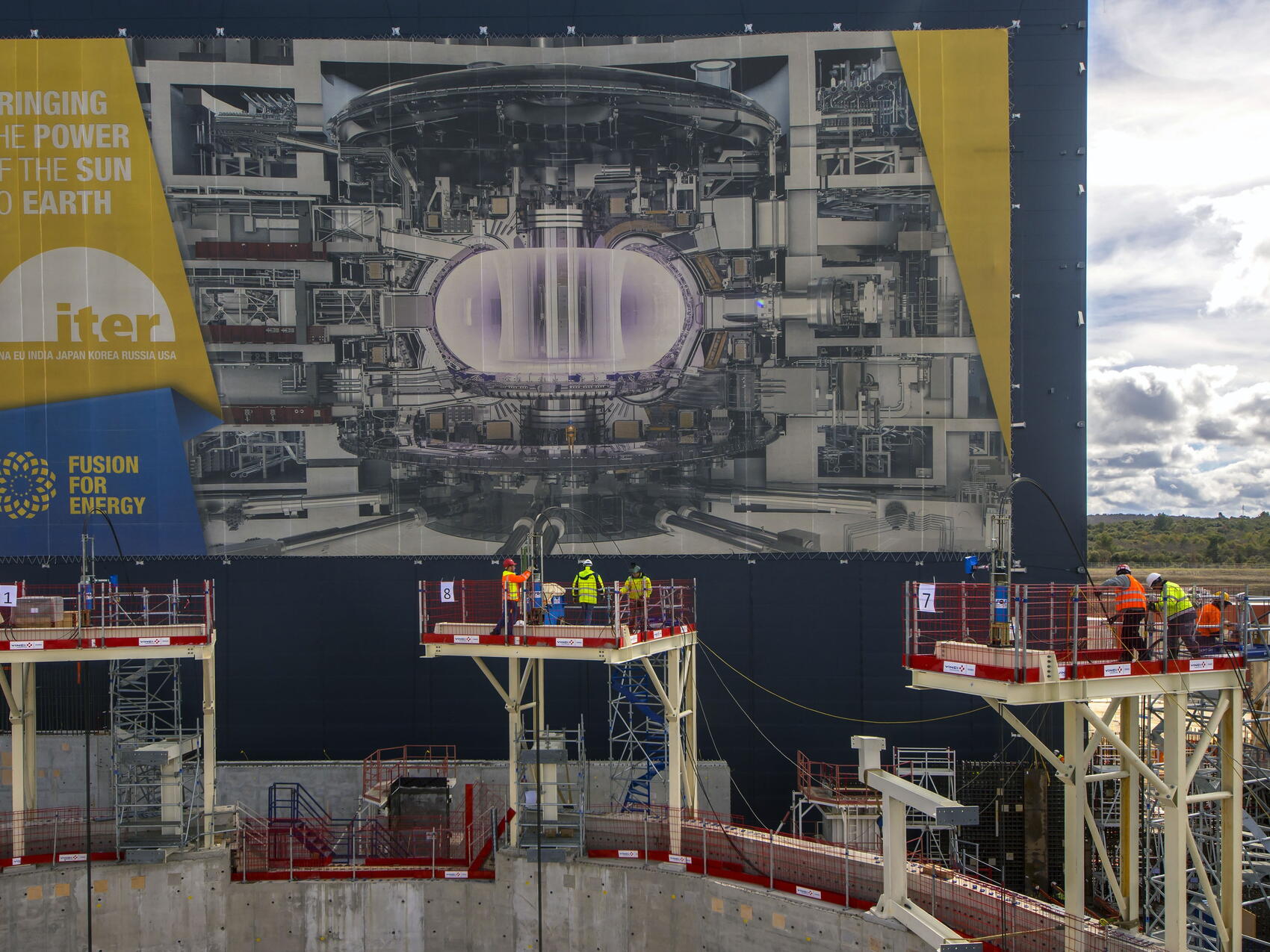

A temporary roof for the bioshield

In August of last year, a circular platform—the "lid"—was installed deep inside of the ITER bioshield, effectively splitting the well-shaped work area into two. The 140-tonne steel structure was designed to protect the workers active in the basement levels while offering storage for the activities underway on the four above-ground levels.

Eight hydraulic jacks—positioned on sturdy platforms distributed around the top of the bioshield—slowly pulled on cables that were attached to the lid in an operation lasting three hours.