Diagnostics

What is the plasma shape? Ask the flux loop

15 Oct 2018

-

K.D.

Inside the machine, the flux loop diagnostic will provide important information to operators on the boundary shape, energy and stability of the plasma.

More than 200 flux loop magnetic sensors will be installed on the interior surfaces of the vacuum vessel to pick up variations in the magnetic flux expelled by the plasma. In addition, four ex-vessel loops will completely circle the exterior of the plasma chamber.

In ITER, arrays of magnetic diagnostics generate signals to control the position and geometry of the plasma, measure current in the plasma and machine structures, and determine the magnetic equilibrium. Measurements go directly to the control systems, making the proper functioning of these instruments essential for machine operation. Equilibrium information will also underpin all other measurements in the machine, linking their information to the correct region in the plasma.

"In the most recent pre-qualification tender phase, we worked with specialists to arrive at cables that fully satisfy ITER's specifications," says Philippe Gitton, diagnostic engineer. "The selected supplier Thermocoax (France) has successfully developed 1.9- and 3.0-millimetre-thick coaxial cables with a copper core, alumina insulant, stainless steel sheathing, and an added layer of copper coating to reflect the microwaves and hence avoid over-heating."

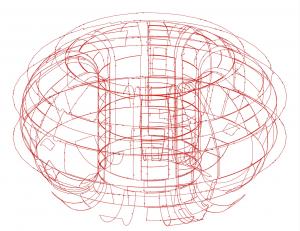

One array, the vacuum vessel flux loops, will be distributed over the surface of the vacuum vessel as 234 individual sensors. Formed from lengths of slim coaxial cable shaped into closed loops, each one senses variations of the magnetic flux expelled by the plasma. These variations create voltage in the closed loops, which can in turn be measured by electronics in the quiet zone of the Diagnostics Building. The flux variations are used to calculate evolution in the shape of the plasma.

For more than four years, the ITER Organization has been collaborating with industry to develop these sensors made from a particular type of mineral-insulated coaxial cable. The cable can withstand the harsh electromagnetic fields, radiation and temperature conditions inside the machine.

"In the most recent pre-qualification tender phase, we worked with specialists to arrive at cables that fully satisfy ITER's specifications," says Philippe Gitton, diagnostic engineer. "The selected supplier Thermocoax (France) has successfully developed 1.9- and 3.0-millimetre-thick coaxial cables with a copper core, alumina insulant, stainless steel sheathing, and an added layer of copper coating to reflect the microwaves and hence avoid over-heating."

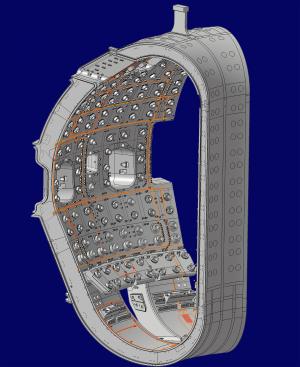

Thin and light, but ever so important. Nearly two and a half kilometres of vacuum vessel flux loops (shown in orange on this sector) will help ITER operators determine magnetic equilibrium and shape.

ITER engineers will be in charge of overseeing the installation of the flux loops—work that will get off to a start as soon as the first vacuum vessel sector arrives at the Assembly Hall and continue as the individual sectors are assembled to form the final torus in the machine pit. The bulk of the coils are on the plasma side of the vessel, but four ex-vessel flux loops wrap around the full circumference of the vacuum vessel using special connections hidden between the thermal shield and the vessel.

"We will be forming the flux loops by hand on site from terminated cables provided by our supplier," says Gitton.

The loops hug the inner vacuum vessel wall, attached with novel fasteners that act as heatsinks in order to keep the temperature of the cables below 250 ˚C. A fastener is needed every six centimetres—so a total of 2.4 km of cable will require some 40,000 fasteners. Between clips, installers will use a specialized tool to add some curve to the cables, giving them the slight amount of play that will be needed as the vacuum vessel and loops expand and contract during different phases of operation and maintenance.

The first batch of equipment arrived last month, in respect of an ITER Council schedule milestone.