Last phase for Korean sector #6

On 7 September, contractors from Hyundai Heavy Industries in Ulsan, South Korea, initiated the final fabrication activities for vacuum vessel sector #6: the assembly of four completed segments into the final D-shaped component, plus the installation of upper and lower port stub extensions. At the end of this first-of-a-kind undertaking, the first 440-tonne ITER vacuum vessel sector will be ready for shipment to France.

On the shop floor in Ulsan, a curtained-off clean space has been created around the assembly platform that supports the building blocks for ITER first vacuum vessel sector: four poloidal segments ranging in weight from 35 to 125 tonnes. When assembled and welded, the final D-shaped component will measure 13.8 metres in height, 6.6 metres in width, and 7.8 metres in length.

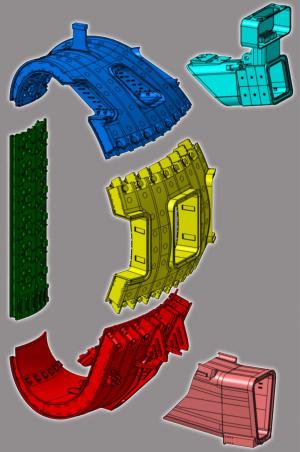

The vacuum vessel is a double-walled component, with 34 to 75 cm of space between the inner and outer steel shells. "Space" is rather a misnomer, however, because the interspace will be nearly completely filled with in-wall shielding blocks (packs of borated stainless steel plates), cooling water channels, and steel supporting ribs. The interspace of Sector 6, for example, contains 850 blocks of in-wall shielding and 850 supporting ribs. Inside the vessel, 172 flexible support housings are welded for the attachment of the blanket shield blocks while outside, two port stub extensions are attached to the sector's upper and lower port stubs through splice plates.

All of this complexity makes the final assembly stage quite challenging. Activities will be carried out in the following order: TIG welding of the inner shell (full penetration welds), followed by welding of structural ribs (so-called "t-ribs") and flexible support housings, keys, the installation of in-wall shielding, and—in the final activity to complete the segments—TIG welding of the outer shell (full penetration welds). One hundred percent volumetric inspection is required as a nuclear safety requirement.

¹ The Vacuum Vessel Project Team reunites staff from the European, Korean, Indian and Russian Domestic Agencies with staff from the ITER Organization in regular meetings to improve the overall efficiency of vacuum vessel procurement execution.

² An Agreed Notified Body (ANB) is a private company authorized by the French Nuclear Regulator ASN to assess the conformity of components in the pressure equipment category (ESPN).