Cryostat lower cylinder

Another major assembly achievement

7 Sep 2020

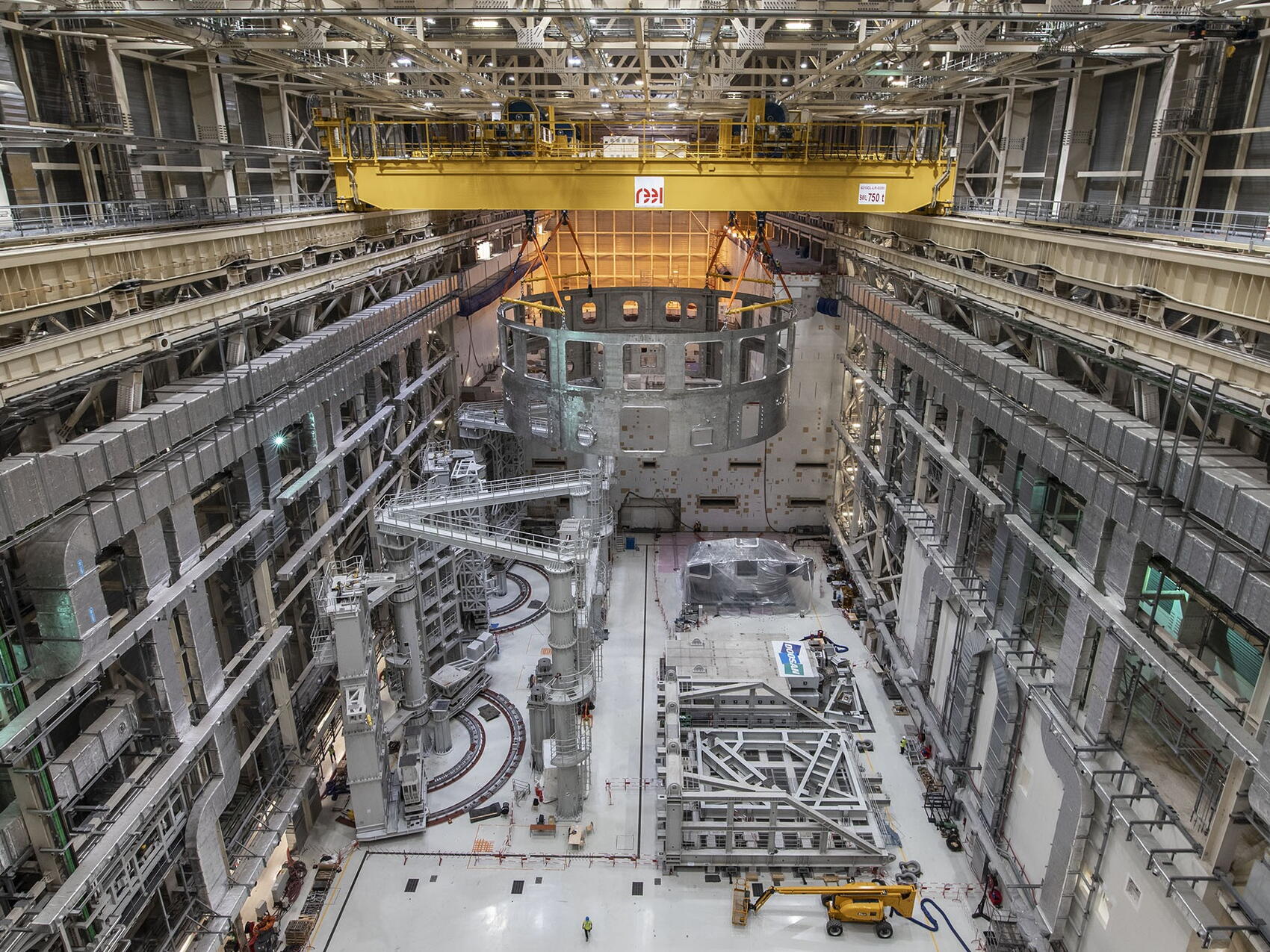

The setting, the atmosphere, the tension, and the sequence of operations were similar, but the challenges were slightly different. The cryostat base, which was inserted into the assembly pit back in May, was an exceptionally heavy, uniform and rather rigid component. The ring-shaped lower cylinder, although much taller (12 metres vs 4), was a considerably lighter load (375 tonnes vs 1,250) and—due to its diameter, thickness and many large openings—more "flexible" and likely to deform. In addition, its mass was unevenly distributed: on one side, the neutral beam port area added significant weight, which required a specific rigging arrangement.

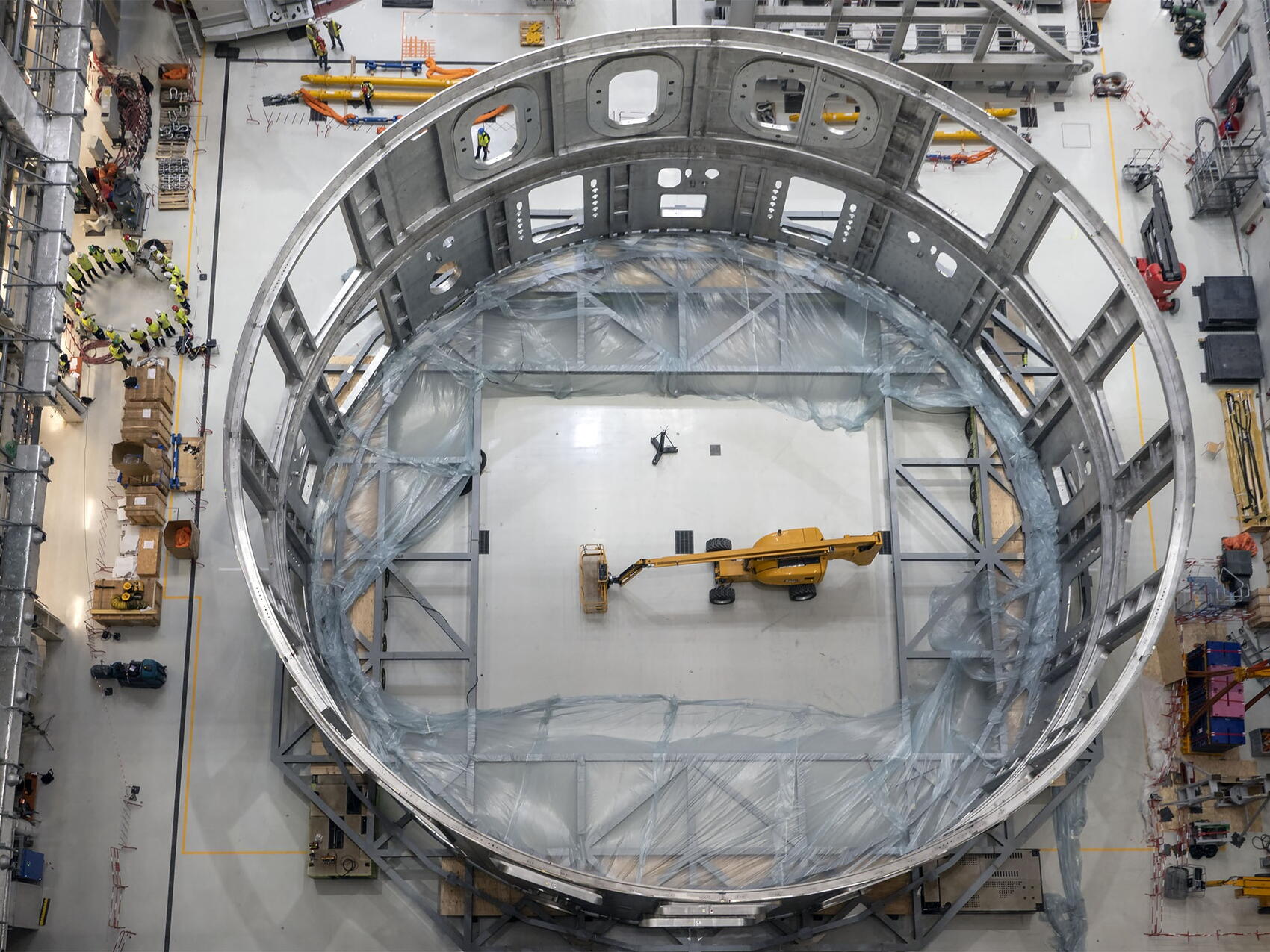

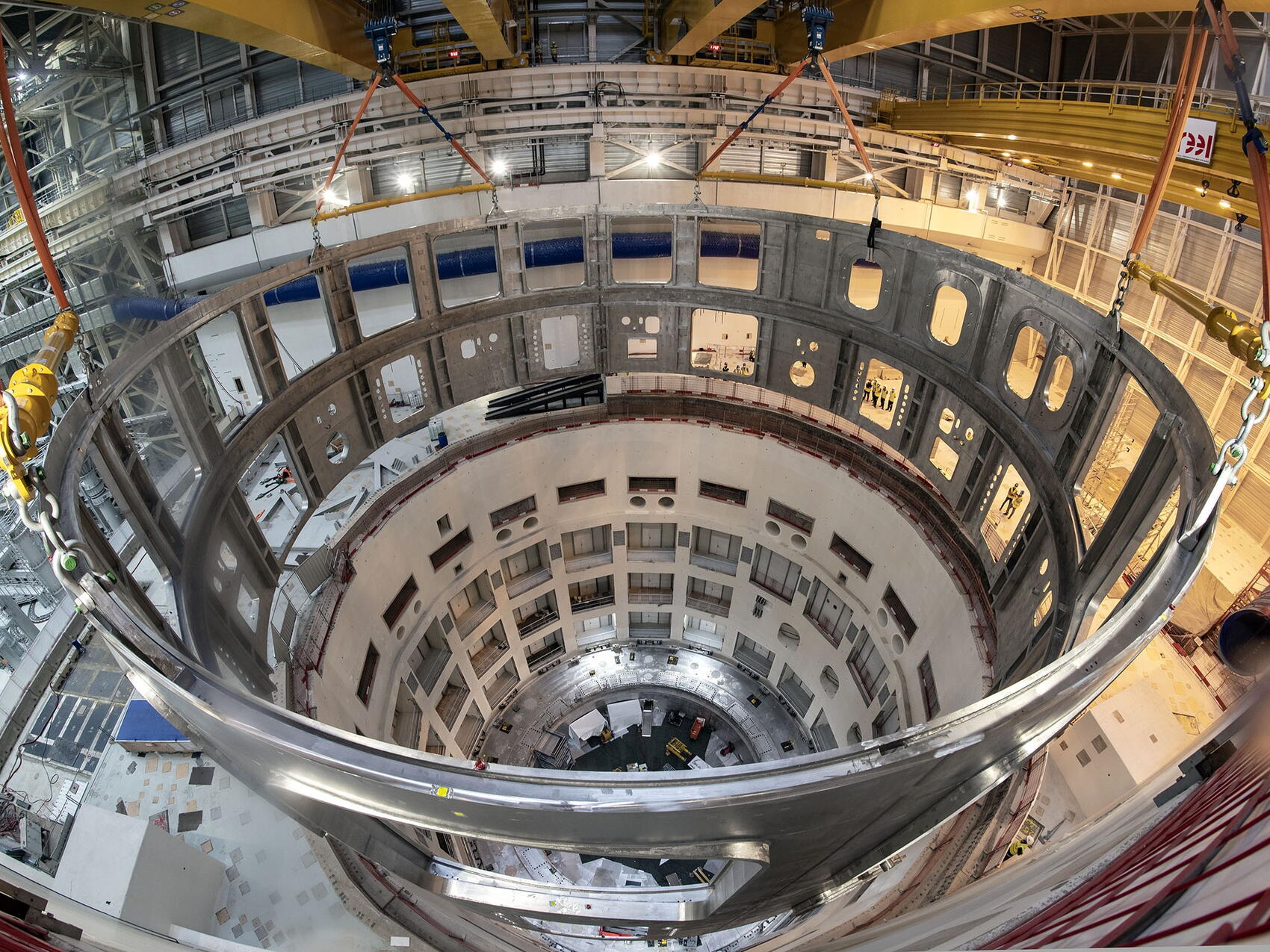

Another image out of a science-fiction movie: the cryostat lower cylinder is slowly lifted prior to its transfer and installation in the assembly pit.

For more than one year, since April 2019, the cryostat lower cylinder had sat in storage, solidly encased in its steel frame and carefully cocooned in airtight material. On 22 August 2020, a 192-wheel self-propelled transport trailer slowly transferred the component into the Assembly Hall, passing through the wide door with very limited clearance.

Preparing for the lifting, transfer and insertion of the cryostat lower cylinder took the better part of one week, including laser measurements, the installation of complex rigging, the connection to the overhead crane, and finally a test lift to determine the importance and range of deflections.

Some 15 hours after the beginning of operations, the cryostat lower cylinder reached its near-final position above the base section. Another week of adjustments, and the welding operations can begin.

On 31 August everything was ready, and the cautious, progressive process of lifting and transferring a steel ring the diameter of the Stonehenge stone circle could begin.

By mid-day, the lower cylinder hovered just about the mouth of the Tokamak pit (see video below). An empty well at the time of cryostat base insertion, the pit has since been equipped with a number of protruding components that reduced already tight clearances to less than 10 centimetres at the narrowest points. Alignment with the cryostat base and the openings in the bioshield wall meant also that stringent rotational tolerances had to be met.

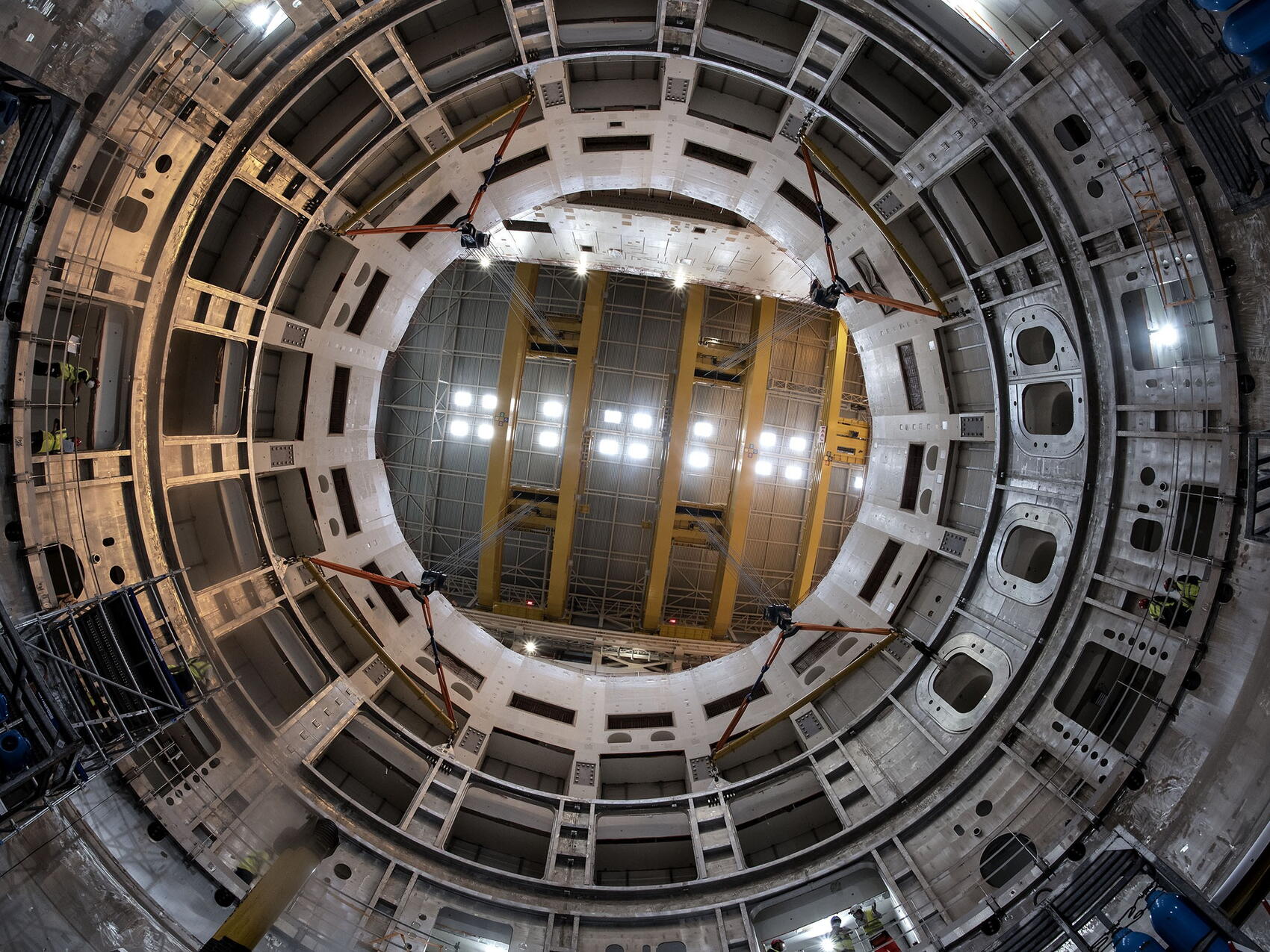

Watching the huge and almost frail component slowly slide down the pit, each opening in the steel ring aligning with the corresponding opening in the concrete bioshield, was an unforgettable experience. As the lower cylinder settled on temporary hydraulic jacks, just a few centimetres above the base, one felt a sense of awe for the precision engineering that had just been demonstrated.

Now, one week later, the lower cylinder is settled in its final position. The gap between the two cryostat sections has been reduced to just 6 millimetres or less and automatic welding operations are ready to start. Expected to last 4 to 5 months, the task will be carried out by specialists from MAN Energy Solutions—the same Indian Domestic Agency contractor that was in charge of assembling and welding the cryostat segments in the Cryostat Workshop.

Watch a video of the operation on 31 August here.