Ensuring port plugs will work as planned

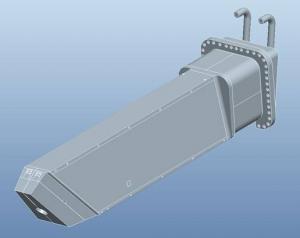

The stainless steel plugs sealing off each tokamak port opening are not only massive, they are also complex—carrying and protecting some of the precious payloads of the machine, including diagnostics and heating system elements that are critical to efficient operation. To ensure that each port plug performs as required, a stringent battery of environmental and functional tests is planned before installation.

Fourteen port plugs at the equatorial level and 16 at the upper level will host diagnostics, elements of the ion and electron cyclotron heating systems, and test blanket modules. These 30 plugs—designed to be removed for maintenance—are subject to stringent availability targets. To meet these objectives, ITER engineers plan to test the port plugs before installation on the machine and after any refurbishment during the operational phase.

Test stands have been designed to perform both environmental tests (for example, appraising leak tightness under thermal cycling and high pressure) and functional tests. Three stands will be installed on site at ITER to test the port plugs after they are delivered and before installation on the machine; a third will be delivered directly to the European Domestic Agency for the testing of the plugs under its responsibility. Once operation begins, two of the stands will be installed in the nuclear environment of the ITER Hot Cell to test the plugs after refurbishment or maintenance during operation.

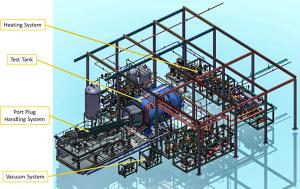

The Russian Domestic Agency is procuring the four test stands for delivery between 2022 and 2024 through sub-contractor GKMP. Each test stand is composed of a test tank, a heating system, a vacuum system, and handling and control systems.

Tests to ensure unique requirements can be met

Some of the biggest technical challenges port plug manufacturers have to overcome are related to the unique environment in the ITER machine: the components have to withstand relatively rapid thermal cycling without breaking the vacuum seal that they represent in the port opening.

"Port plug material expands greatly," explains Yury Rumyantsev, technical responsible officer at the Russian Domestic Agency. "When stainless steel is heated from room temperature up to 240 °C it expands about 3 mm/per metre, which opens up the possibility of leakage in the port opening. To meet this challenge, manufacturers have had to select a specific metallic sealing gasket and fabricate the flange for this gasket with very high precision."

"Very few applications have this combination of thermal cycling, high vacuum and nuclear requirements," says Olesia Solovyeva, director of the ITER project at GKMP. "Our job is to provide the testing facilities that can be used to make sure the port plugs stand up to the challenges they will find in the ITER reactor."

One set of tests will submit the port plugs to thermal cycling at high vacuum. Engineers will perform three rounds (cycling from room temperature to 240 °C) and check for helium leaks coming from the port plug assemblies. Tests will also be performed to verify that the cooling circuits can handle both high pressure and pressure drops. Outgassing rates will be measured to make sure the vacuum is protected as temperature and pressure are applied.

To run the tests, the port plugs will be installed in a test tank—a 40 m³ vacuum chamber that will emulate the vacuum conditions of the ITER tokamak. The heating system used to cycle the temperature consists of a loop circulating water inside the port plug and around the test tank at 40 atmospheres of pressure to heat and cool the plug across the test range temperatures.

Functional tests will depend on the nature of the diagnostics housed in the port plug—and by way of example, may include tests for electrical continuity, detector calibration tests, tests for the alignment and cleaning of diagnostic mirrors, or tests of shutter actuation.

"There is one specific case that has to be carefully handled by the port plug test facilities," emphasizes Thierry Cerisier, ITER technical responsible officer for the project. "If an assembly under testing fails in such a way that it causes a water pipe to break, this could cause the pressure inside the tank to soar to the point of damaging the port plug. To mitigate this, special overflow chambers have been included in the design of the test stands to relieve the pressure that might otherwise destroy some of the key elements on the port plug boundary."

An important milestone halfway through the project

"This year is the most important in the project lifecycle, because it's the year we start manufacturing," says Solovyeva. "The first test stand will be delivered to the ITER site in June 2022, and a second will be delivered to the European Domestic Agency soon afterwards. While the non-nuclear test stands are being manufactured, we will complete the design of the two nuclear test stands destined for the Hot Cell. These will be delivered to the ITER site in 2024."

"The nuclear-ready stands will also be used during the earliest testing phase, before the port plugs are installed for the first time on the machine," says Rumyantsev. "Then when this phase ends, those stands will be modified slightly and transferred to their permanent home in the Hot Cell, where they will be used to test port plugs after they are repaired or upgraded."

The three ITER port plug test facilities will be installed in the European Poloidal Field Coils Winding Facility on site, where the "clean" conditions are ideal for the tests, and space has been made available courtesy of the European Domestic Agency. The first non-nuclear test stand will arrive on site in 2022 and will be installed just as coil fabrication is ending.