The last step before plasma operations

ITER's approach to commissioning makes a clear distinction between system commissioning and integrated commissioning. Integrated commissioning is a carefully orchestrated process that occurs only after all components have been tested independently.

"If I'm going to commission the cryoplant, I need to first perform system commissioning on the water and electricity systems separately, because I need these systems during integrated commissioning," explains Isabel Nunes, Commissioning Operations Responsible Officer in the Operations Division. "Integrated commissioning is putting together a set of systems and making sure the integrated whole performs as expected, so we can proceed to the experimental phase."

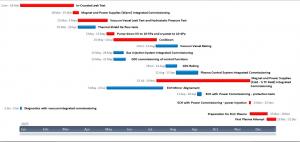

Integrated commissioning will be performed before each stage of ITER operation, after systems and components are installed and individually commissioned. The first phase of integrated commissioning, in preparation for First Plasma, is scheduled to start on 2 January 2025 and to end on 20 December of the same year with the demonstration of First Plasma.

Before First Plasma

Even though integrated commissioning starts in early 2025, intense preparations are already underway. "For me, the preparation work is the most stressful—and it has already started," says Nunes.

Nunes is currently breaking down the activities in the baseline schedule into finer detail, identifying dependencies and planning resources—both technical and human. In collaboration with different teams, she details steps and required conditions, or pre-requisites—including which investment protection functions need to be commissioned first, and which safety functions need to be active before integrated commissioning begins. Another very important part of the preparation is risk assessment, which helps minimize the impact of unexpected events through careful planning.

"My current work involves dedicated meetings with the people responsible for all the different systems that play a role in a given activity," says Nunes. "Take, for instance, the process of cooling down the superconducting coils to minus 268.65 °C. It sounds like a simple process, but it is actually very complicated. We are discussing the detailed steps now."

"In general, we define the sequence of steps within a specific activity. For this process to work, all the stakeholders from the different systems need to be involved, systems such as the cryoplant, the vacuum vessel, the magnets, the safety functions and the interlock functions. It is important to consider the operating limits of the different systems at this stage. The coils cannot be cooled too fast—for example, mechanical stresses build up as a result of cooling, and there is a limit to how much of that stress the coils can handle."

The outcome of all the work Nunes and colleagues are now doing will be a set of procedures to follow during integrated commissioning. The Primavera project management tool is used to document milestones and dependencies between activities. Where there is a dependency, actions must be performed in sequence. Cool down, for example, requires the coils to be in vacuum inside the cryostat and thus can only be performed after the cryostat pump down.

Integrated Commissioning officially starts when the cryostat lid is closed and responsibility is handed over to Operations. "The first activity will be to pump down the cryostat," says Nunes. "Following that, we leak test the in-cryostat components. Then, we cool down the coils and thermal shields, and we condition the vacuum vessel by baking it. After that, we will be ready to start energizing the superconducting coils in preparation for the First Plasma campaign. That's when the experiments start."

After First Plasma

Immediately after First Plasma comes "Engineering Operations," a short phase whose main purpose is to demonstrate operation of the superconducting coils at full performance. During this phase, tests will be conducted to make sure the magnets can achieve the 15 MA plasma current scenario at a toroidal field of 5.3 T, which will ultimately be used to produce 500 MW of fusion power.

Engineering Operations will be followed by Assembly Phase II, where the blanket and divertor and many other components—such as diagnostics—will be installed in preparation for the first Pre-Fusion Power Operation experimental campaign. Once system components are individually commissioned, Integrated Commissioning 2 will start.

"Many of the processes will be the same as during the first phase—basic pump down, cool down and baking," says Nunes. "In many ways, it will be easier the second time, because we will have the experience. But we also need to consider the new components and new systems and all the new challenges we have already started to analyze."

This carefully orchestrated process will be performed after each assembly phase to bring the machine to full operational capacity.

"In summary, during integrated commissioning we build up to readiness for plasma operations by integrating all the separate systems and demonstrating that they work together."