Radial beam fits just right

When describing operations inside the ITER in the assembly theatre, one is invariably tempted to call up images from the realm of science fiction. How else to convey the awe and puzzlement that every component and every operation trigger?

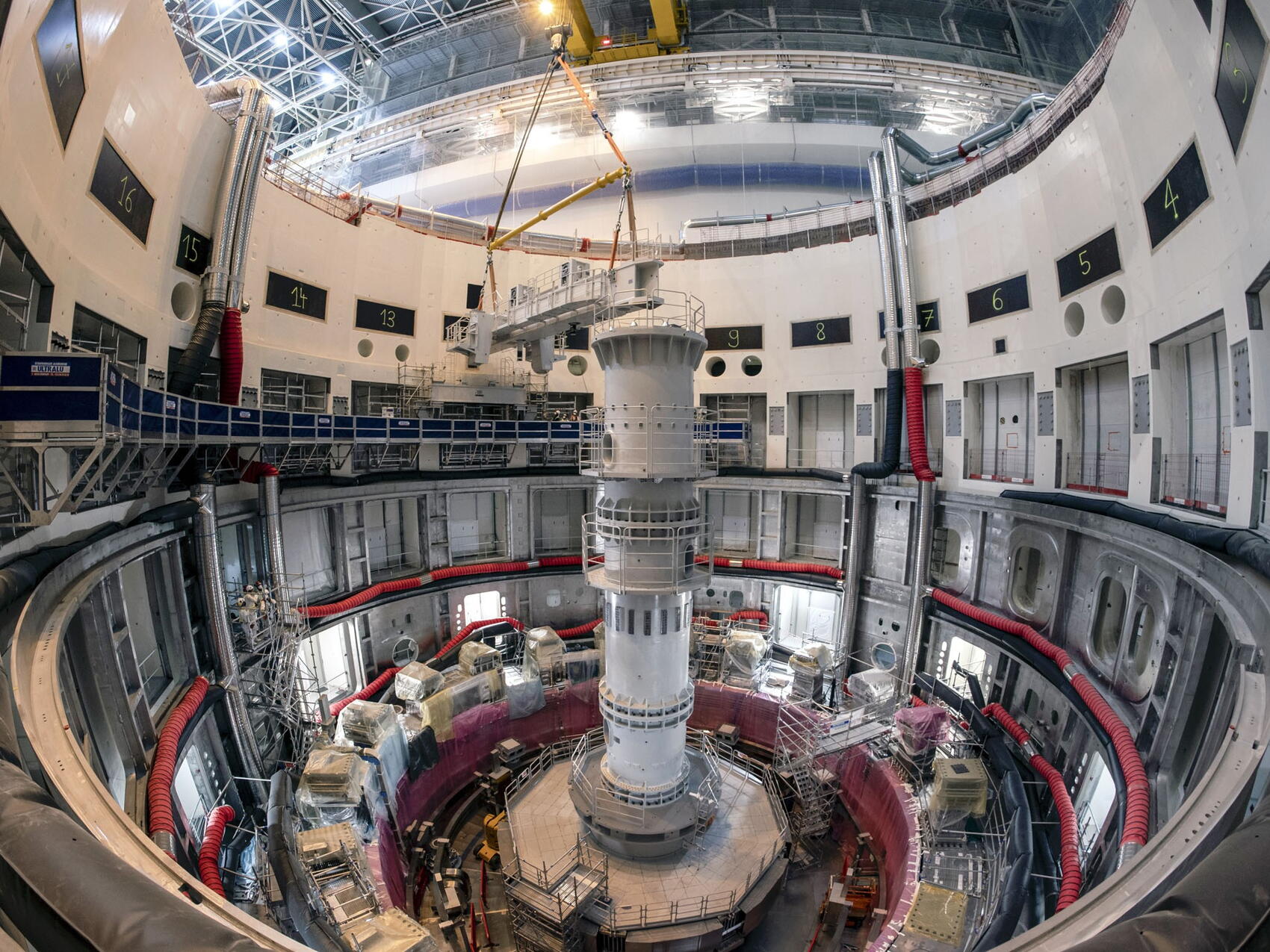

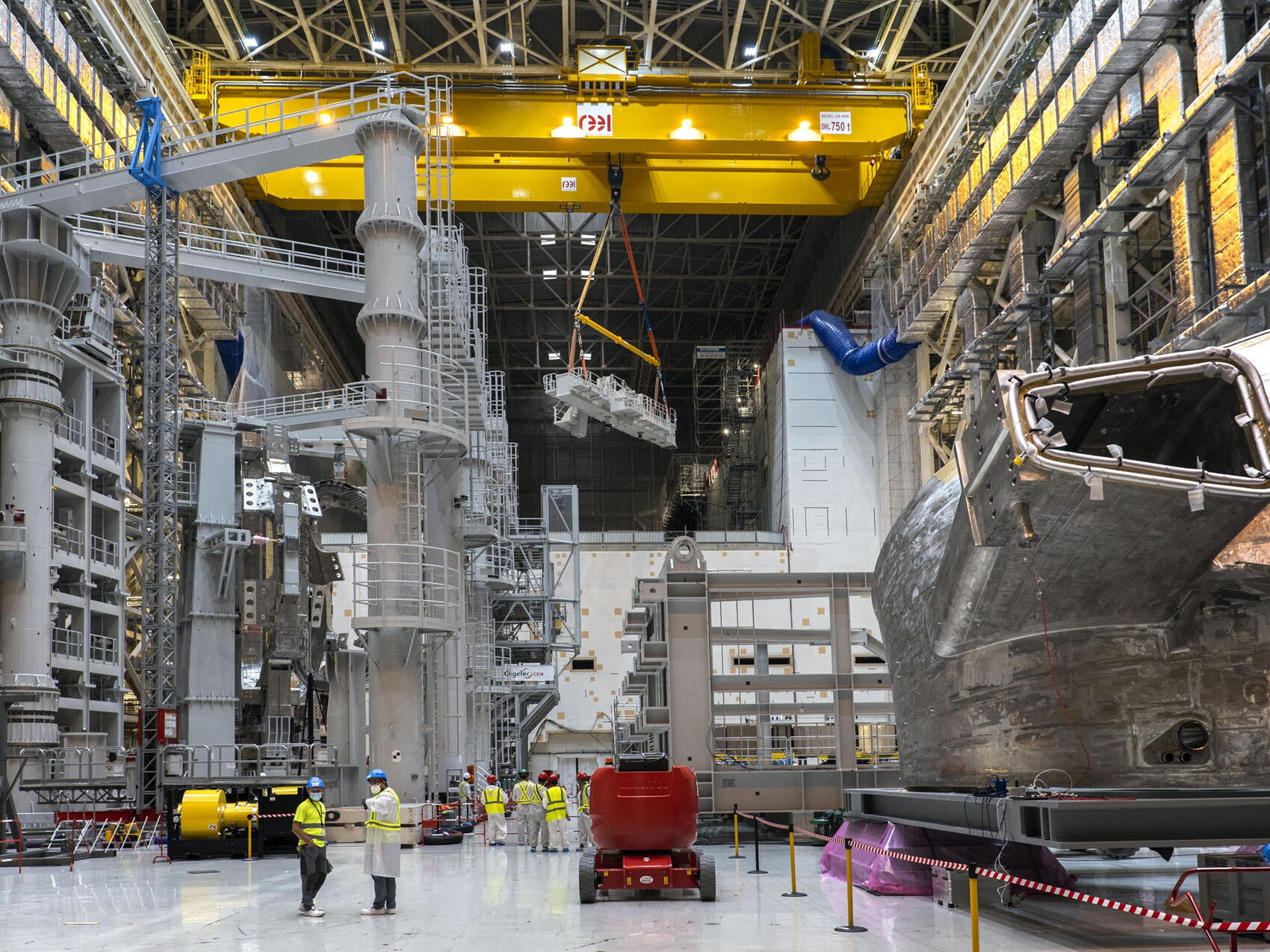

The installation of a test radial beam, on Wednesday 8 September, was one of those moments when it felt like being witness to something utterly alien. A radial beam is not, in itself, a spectacular component: 14 metres long and weighing approximately 70 tonnes, it is part of the massive in-pit assembly tool that will rise at the centre of the Tokamak pit for the duration of vacuum vessel assembly.

However once hanging in the air and slowly moving along the entire length of the assembly theatre, its shape and pace were strongly evocative of slim spaceship—the bow turned toward its destination, an upper deck gangway, and openings in its hull like rocket exhausts.

And when the spaceship docked on top of the recently installed central column, it was as if a long journey through space had come to an end. One almost expected alien creatures to come out of the ship ...

The team managed to have everything prepared in order to complete the trial lift before the installation, scheduled this week, of poloidal field coil #5 (PF5). "There was quite a lot to do in a short period of time," explains Colin Smith, the engineer responsible for the installation of the in-pit sector assembly tooling.

Having verified with metrology that the central column and radial beam support were properly aligned, operators were reassured. "Considering the length of the beam, an offset of just a few millimetres on the central column would have resulted in centimetres of misalignment on the support."

The docking and fitting of the beam, and the final bolting to the top of the column, all fell within the required millimetre tolerances.

Final measurements did reveal an unexpected "slope" in the radial beam itself. "Because we did this test early, we have ample time to investigate whether this slope is acceptable or if we need to perform shimming to compensate for it prior to the installation of the first sub-assembly."