Translating physics limits to millimetres

The manipulation of massive components under tight tolerances presents a formidable challenge.

While reference to millimetres can seem commonplace, satisfying ITER's millimetre-level alignment tolerance targets over long distances and with very large components—such as ITER's 17-metre-tall, 360-tonne D-shaped toroidal field magnets—places the challenge firmly in the world of precision engineering.

Put another way, the alignment of books on your shelf to the same precision requirements as ITER's vertical magnets would require a positional accuracy finer than the width of a human hair.

The need for such alignment precision comes from physics. The superconducting coils produce the magnetic field that confines the plasma, and the plasma needs to be as close to perfectly symmetric as possible—a perfect doughnut shape without bumps or lumps on its surface. A bumpy plasma can cause very large localized power fluxes on ITER's internal wall and is vulnerable to sudden stops, or disruptions. Thus, precise physics principles have to be used to guide the assembly of ITER's magnetic and first-wall components to ensure that the assembled tokamak is capable of achieving its fusion goals.

Similar to the temperature of the porridge in the 19th-century fairy tale Goldilocks and the Three Bears, the translation of these physics limits to assembly millimetres needs to be "just right." Set the tolerances too large and we risk assembling a machine unable to achieve its fusion goals. Set them too small and we end up creating a puzzle without a solution resulting in a machine that cannot be assembled.

The animation shows displacements resulting from the energization of ITER's 18 toroidal field coils. (The displacements are magnified 50 times for illustrative purposes.) Maximum displacements are found at the centre of the tokamak where the vertical sections of each D-shaped magnet butt together to form a circular vault (in the ideal case). Once the coils are energized, the assembly gaps left between adjacent coils close. A non-axisymmetric distribution of assembly gaps generates a non-circular vault and hence a non-axisymmetric toroidal magnetic field. ITER's main superconducting magnets will be assembled "warm" (that is, at room temperature), with no current flowing in them. However, they will operate at cryogenic temperatures (close to 4 Kelvin, or -269 °C) and the coils will be "energized"—carrying the large currents that will produce the strong magnetic fields required for fusion. Industry-leading ANSYS simulations provided by the European Domestic Agency Fusion for Energy allow the mapping of warm assembly configurations to the cold/energized operating configurations required to produce plasmas, as shown in the animation of the toroidal field coil energization step to the right.

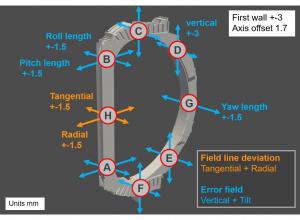

The dimensional tolerances of ITER's magnets are controlled via a sequence of detailed measurements taken at every step of a coil's manufacture and assembly. These measurements use lasers to track the precise geometry of each coil from its birth in the factory to its final installation the tokamak pit. The measurement of deviations from ideal "as-designed" parts on a computer screen to "as-built" coils ready for installation at ITER forms a vital part of our assembly strategy. The assembly tolerances required to align a pair of toroidal field coils in the Tokamak pit are shown in the image below.

The proximity of an as-built operating configuration to our physics limits requires a further "translation" of the magnet's physical position into the "physics units" within which our limits are defined.

This is possible thanks to the support provided by the Russian Domestic Agency which enables the generation of precise 3D magnetic field maps generated by these as-built coils deformed under their operational loads. From these maps, the proximity to wall heat load and plasma performance limits is assessed by applying physics modelling tools respectively developed within the ITER Organization and provided by the US Domestic Agency for each of these two limits. The limits themselves are based on extensive experimental studies for ITER, which have been coordinated by the International Tokamak Physics Activity (ITPA).

The original duration for a round-trip calculation—that is, from warm magnet positions to proximity to physics limits—as required by the reverse engineering team responsible for the assembly process used to approach one month. An effort was launched in 2021 to accelerate this round-trip analysis in support of the assembly and installation of the first ITER vacuum vessel sector module (#6). The discovery of fast proxy models based on a spectral filtering technique enabled a fifty-billion-time speed-up (5 × 10^10) of the full calculation workflow—from four weeks to 50 microseconds. This acceleration opened the door to Monte Carlo simulations which have processed millions of trials for possible "warm" assembly configurations with regard to their acceptability from the physics point of view. Using this enormous database of assessments it is possible to provide guidelines to the assembly teams to decide whether the assembly configuration that they have achieved is acceptable or not.

Close collaboration between the assembly, reverse engineering, blanket, and science teams has enabled the development of a set of "just right" physics assembly guidelines, as shown above. These guidelines, together with parallel compliance assessments of the tokamak's mechanical interfaces carried out by the reverse engineering team, result in a grounded alignment strategy based on physics acceptability and engineering feasibility.

The assembly of sector module #6 and its positioning in the tokamak pit was successfully implemented according to this integrated alignment strategy for the toroidal field coils. An extension of this approach is underway to include the remaining major coil systems in ITER (6 poloidal field coils and the central solenoid) so that it may be applied to the complete tokamak assembly process.