Cryopump passes site acceptance tests

Cryopumps, which play an essential role in ITER, are not what one has in mind when picturing a pump. A conventional pump creates negative pressure to suck in fluids such as water or air. Cryopumps, on the other hand, are based on a simple law of physics: when a molecule or an atom encounters an extremely cold surface, they lose the better part of their energy and slow down to near immobility; the colder a surface, the more irresistible is its power to "hold" particles. When high vacuum is needed, cryopumps are indispensable to finalizing the initial pumping done by mechanical devices. ITER will use cryopumps to create high vacuum in the (aptly named) vacuum vessel, the cryostat, the "beam boxes" of the neutral beam injection system, and a few other machine components and systems. In early March, the cryopump for MITICA, a real-size ITER neutral beam injector hosted by Consorzio RFX in Padua, Italy, successfully passed site acceptance tests.

The delivery of this first-of-a-kind cryopump, similar in all respects to those that will equip the ITER neutral beams injectors, marks the culmination of a five-year manufacturing effort. Procurement was split between two highly specialized French contractors, Ravanat and SDMS, working under the supervision of the ITER Organization and the European Domestic Agency Fusion for Energy.

"What makes us proud is that this first-of-a-kind pump is the result of a big, unique ITER design," says Robert Pearce, the head of the ITER Vacuum Section. Although a cryopump is a "passive" device with no moving parts, "anything that operates at cryogenic temperature presents considerable challenges."

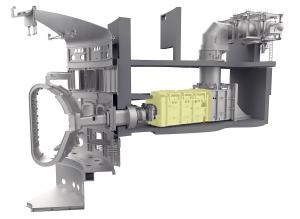

Located inside the injector's "beam box" the cryopump will create the high-vacuum environment indispensable for accelerating and "neutralizing" the energized particles shot into the plasma. Like the torus cryopumps that remove the helium "ashes" from the plasma, the MITICA cryopump will also pump the gas load used in the neutralizing process (see box).

During the accelerating and neutralizing phases, supercritical helium circulating through a dense web of piping will keep the pump's panels at the temperature of 4.5 K (minus 269 °C). However, during the "regeneration" phase, when the gas particles trapped inside the panels need to be released, the same piping will accommodate a flux of gaseous helium at 125 °C—a huge temperature gradient that creates an "accordion effect" in the component's stainless steel circuits.

In the restricted space of the pump assembly (8 metres long, 2.8 metres high and 0.45 metres wide), contraction and expansion is a considerable issue that had to be taken into account during the design. "In a way, it was like designing a whole plant that would alternately contract and expand like an accordion," says vacuum cryopump engineer Jamie Buckerfield. As the MITICA facility is not fully operational yet, it may be some time before the cryopump can be tested at cryogenic temperatures. "We have tested what we could: temperature sensors and the leak-tightness of the pipes at room temperature. But based on the analysis, prototyping and validation phases we have great confidence in our design."

See a 2022 story on MITICA cryopump manufacturing on the Fusion for Energy website.