A four-day "reverse lift"

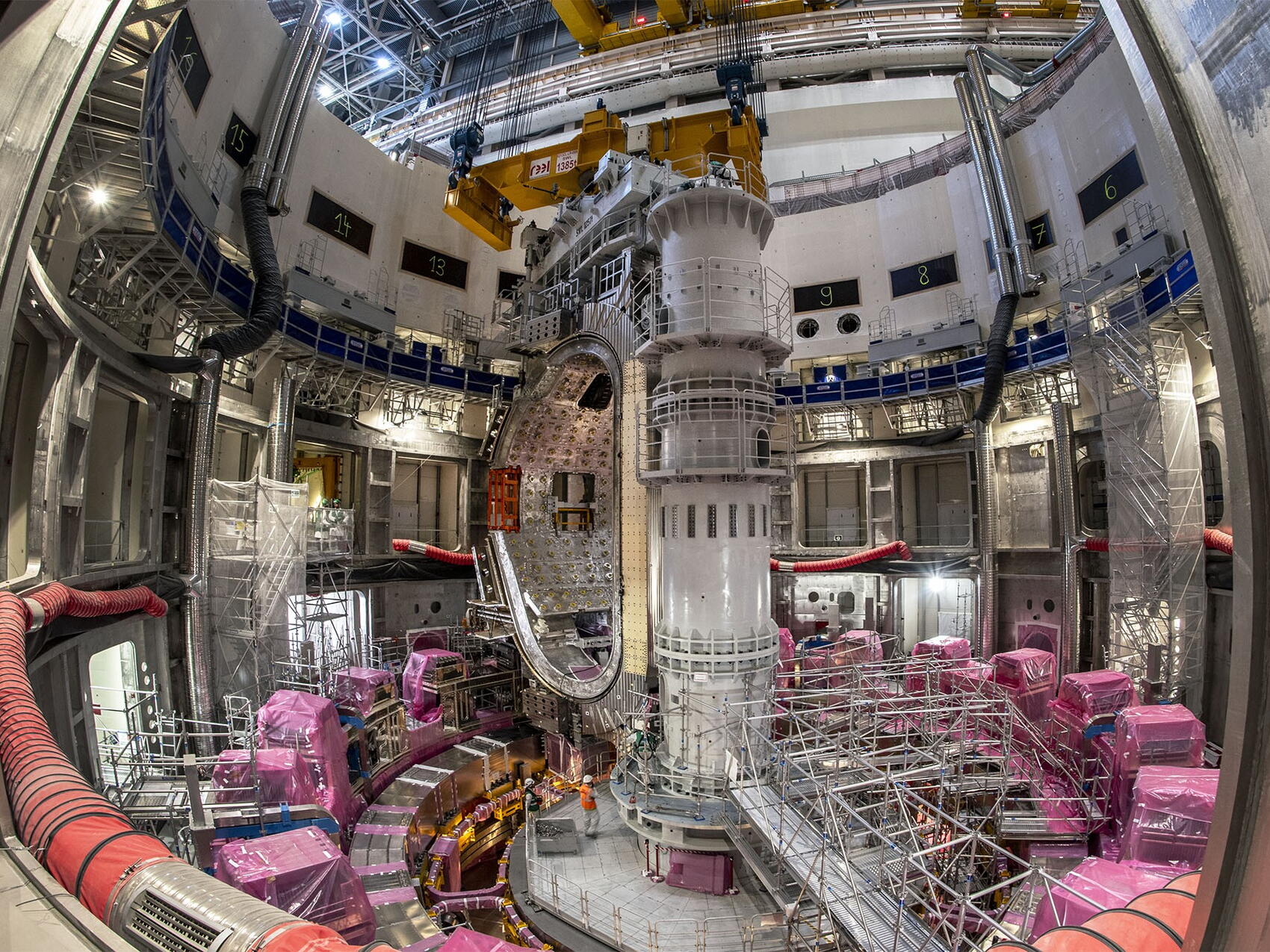

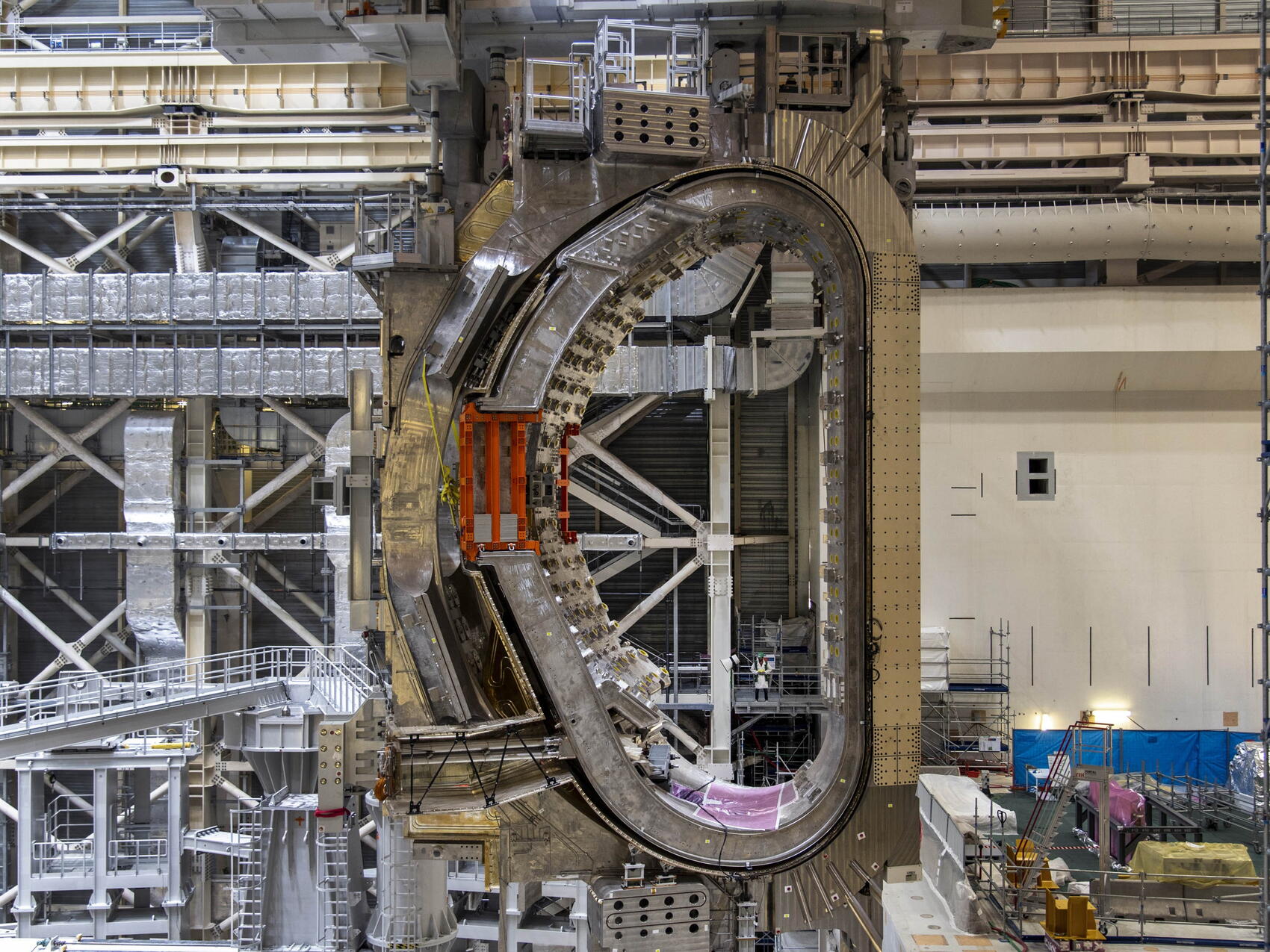

In May 2022, the first of nine sector modules that form the tokamak torus was installed in the assembly pit. In a reverse operation last week, the same 1,350-tonne module was removed, as dimensional non-conformities observed in the vacuum vessel sector's bevel (welding joint) region, combined with corrosion-induced cracks in thermal shield piping, meant that the sector module had to return to tooling in the Assembly Hall for disassembly. Although not foreseen in the original specifications of the assembly tools, the reverse lift operation was performed with the same hardware successfully.

The reverse lift—an operation that took close to four days, excluding advanced preparation activities—did not simply consist of reversing what had been done more than one year before. Procedures had to be adapted and additional guiding systems had to be manufactured and installed. "A lift-off is not exactly a reverse landing," summarizes Daniel Coelho, the ITER assembly engineer who coordinated last week's operation.

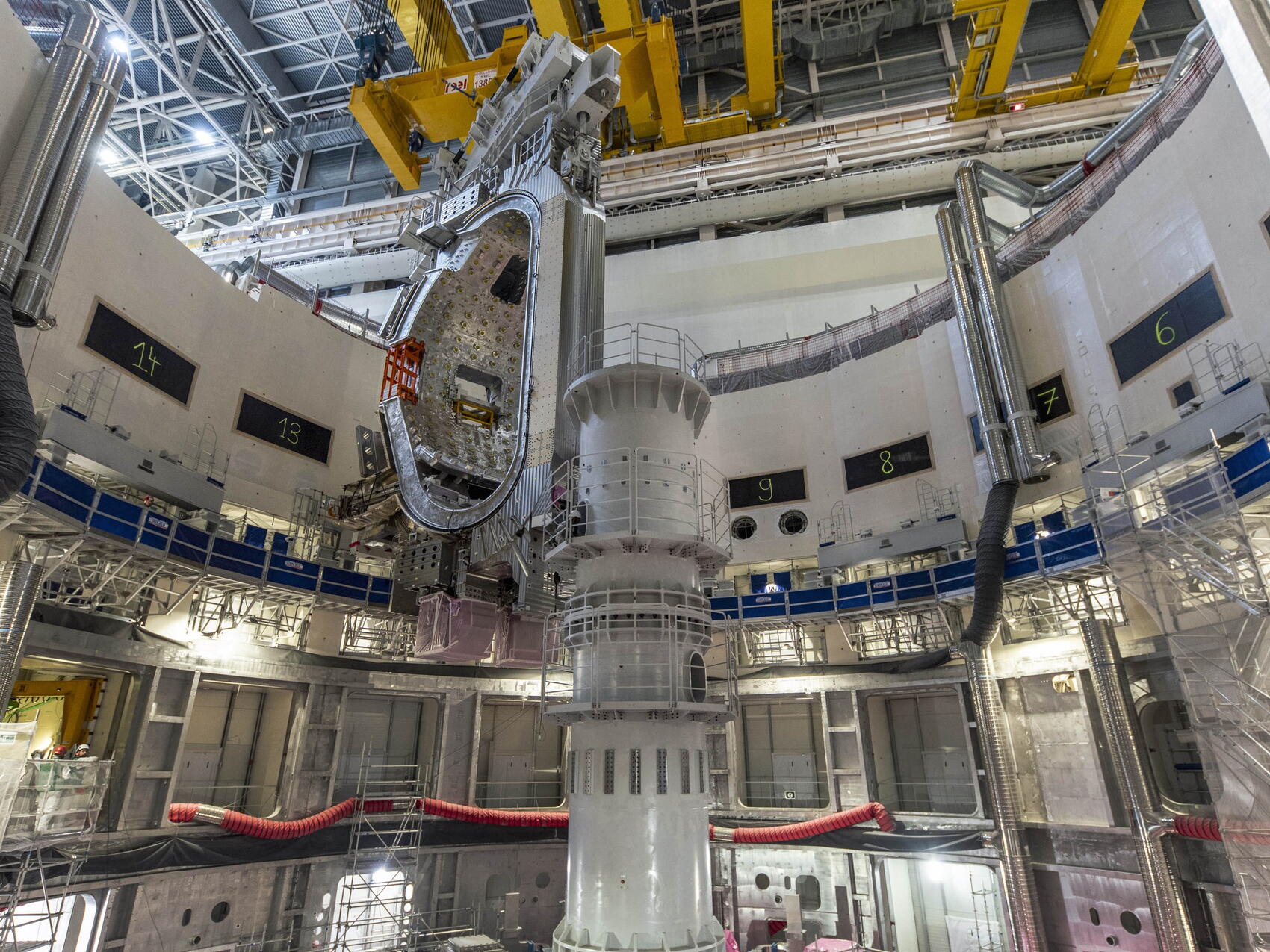

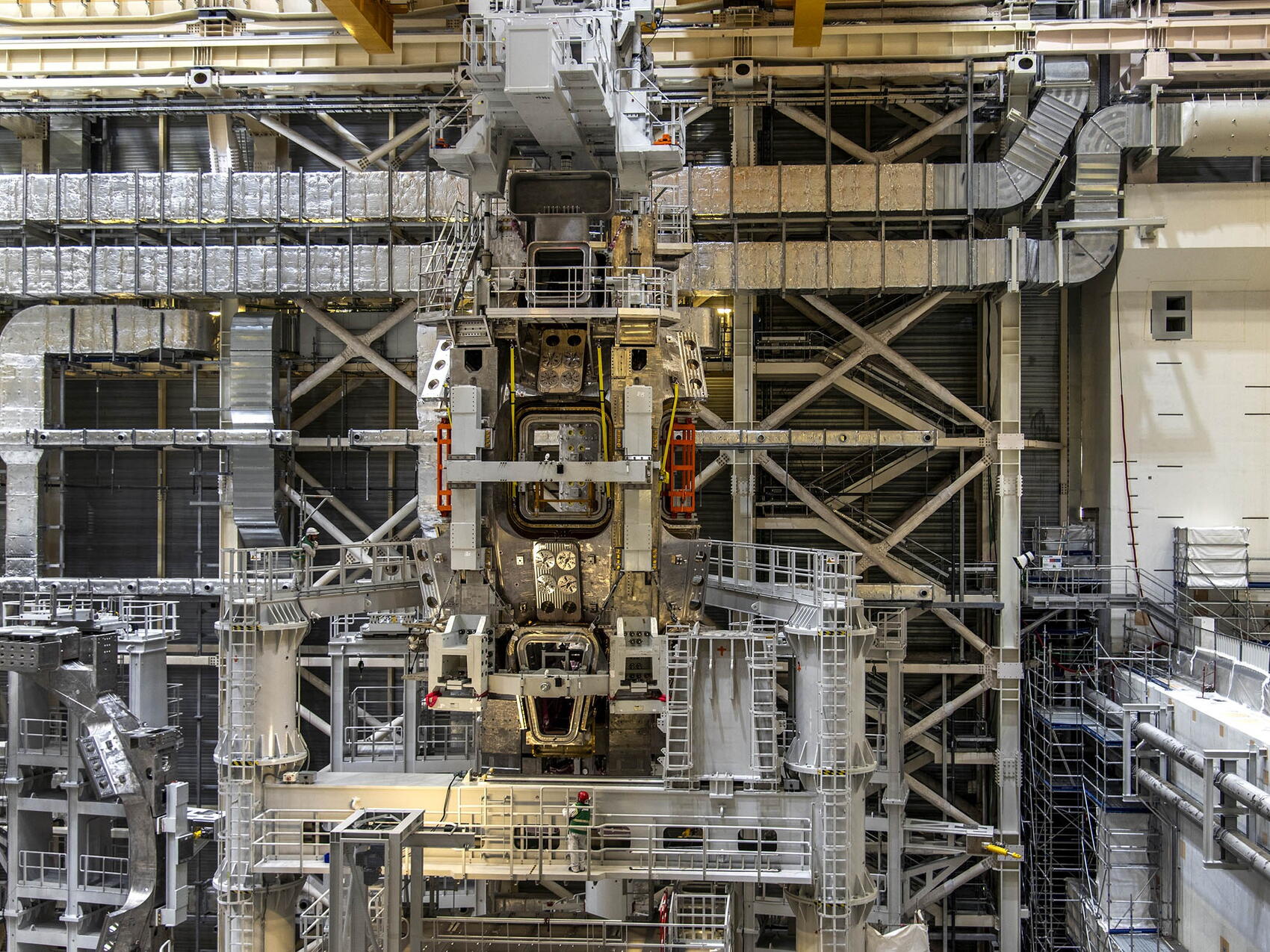

The extraction began in earnest on 4 July with a "pre-lift" that raised the load a few centimetres from its landed position. For the main operation, more than one hundred different steps had been defined, validated and integrated into the lifting procedure—from detaching the module from its moorings in the assembly pit, to lifting and transporting it to the sub-assembly tool on the other side of the wall in the Assembly Hall. To carry out the planned succession of moves—lifting, rotating, advancing, rotating, advancing, lowering—it was essential to determine with utmost precision the relative position of each of the elements concerned: the load itself, the overhead crane's complex rigging and the tool support systems at the receiving end.

Just like during the May 2022 operation, one of the main challenges was to determine the load's centre of gravity. "The module is of a composite nature. When sitting in the pit, the vacuum vessel and the toroidal field coils are not mechanically connected," explains Coelho. "It's only during the lifting phase that, thanks to the bracing tools that attach vacuum vessel and coils together, they become one homogeneous load with a common centre of gravity."

Lessons learned in 2022 were essential to this operation's success. "We have made considerable progress in terms of alignment accuracy and, what is also very important, we operated with the same team. Everybody knew his/her part perfectly, and coordination among the team members was smooth."

Although it was a highly sophisticated operation that relied heavily on sensors and strategically positioned cameras, "spotters" played a crucial part in precision and overall safety. "A sensor will give you an indication. But only the human eye, and the brains to which it is connected, can analyze and understand a situation and take the right decision," says Coelho. On 5 and 6 July, during the actual lifting and landing of the module, close to a dozen spotters closely monitored the most delicate passages: along the pit's central column, over the separating wall and during the insertion into the sector sub-assembly tool.

A towering presence inside the assembly pit for close to 15 months, the sector module is now standing in the tool's embrace. Disassembly activities have already started in preparation for the synchronized opening of the tools' wings and the removal of the toroidal field coils, followed by the removal of the thermal shield panels. By then, the vacuum vessel sector will stand alone in the tool. Once rid of its equipment and "stripped naked," preparation for repairs—starting with metrology to define the metal build-up and machining zones—will begin.

See a video of the lift operation in this edition of the ITER Newsline or on the ITER YouTube channel here.