The last ring

As the massive ring-shaped coil inched its way from the Poloidal Field Coils Winding Facility, where it was manufactured, to the storage facility nearby where it will remain until the moment it is transferred to the tokamak assembly pit, Pierre Gavouyère-Lasserre remembered a decisive moment, 10 years earlier in April 2014. In the vast, empty winding facility on the ITER site, Fusion for Energy, the European Domestic Agency for ITER with responsibility for procuring the five largest ring-shaped superconducting magnets, had organized the "Poloidal Field Coils Information Days." Pierre, currently the Deputy Project Manager for poloidal field coils at Fusion for Energy, helped to present upcoming calls for tender to several dozen European industry representatives who were interested in taking on the challenge. This week, he watched with emotion as the formidable industrial venture launched ten years earlier came full circle: poloidal field coil #3 (PF3)—the final poloidal field coil produced for the ITER machine, was now safely stored next to its quasi twin PF4 and the smaller PF2.

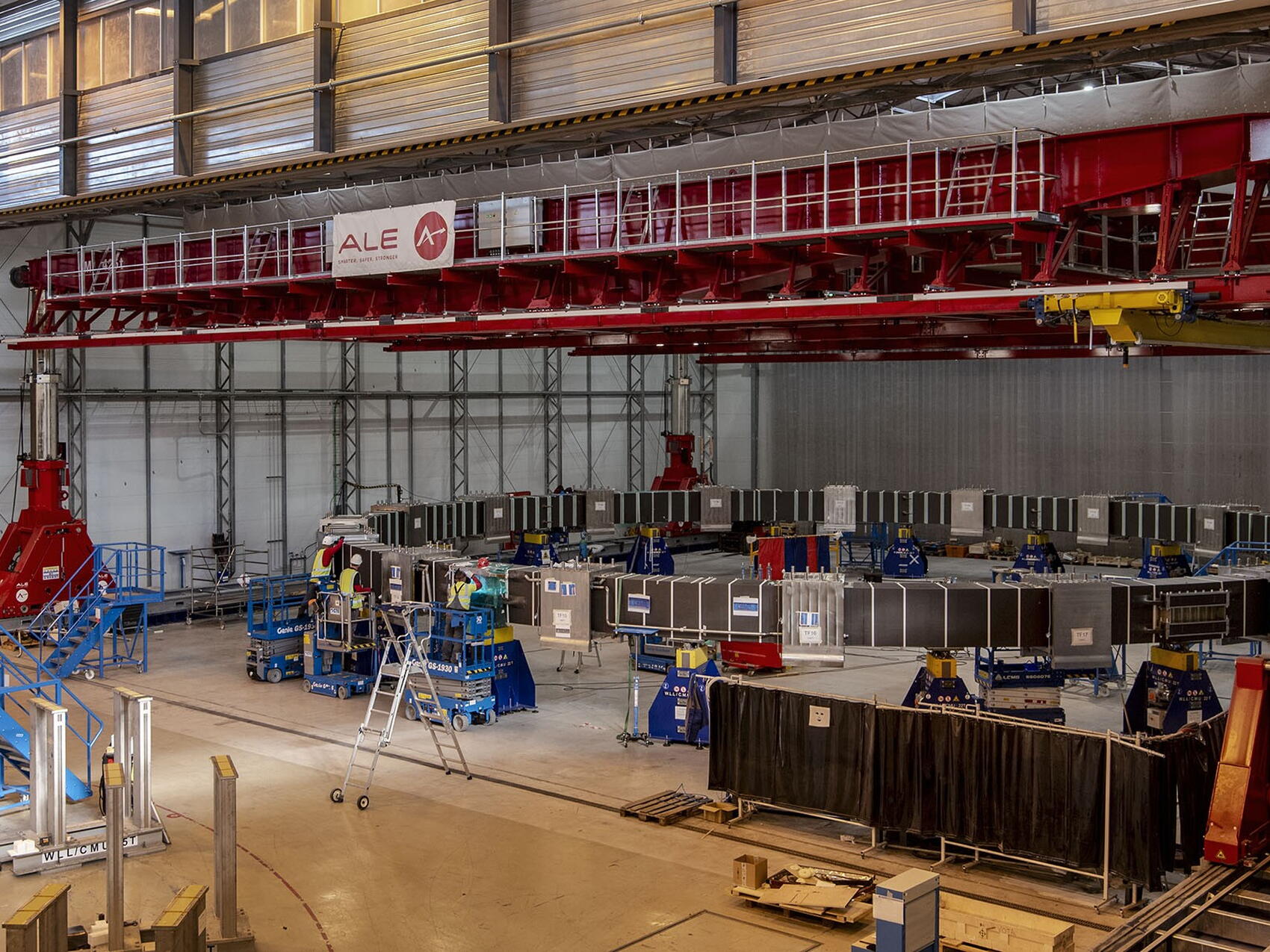

The fabrication of PF3—one of the two largest ring-shaped coils, measuring 24 metres in diameter—marked the high point of technical and organizational expertise that had been accumulated since manufacturing began in the Winding Facility in late March 2017. The first coil to come off the production line in 2021 (PF5) had required three and half years of work. Although 40% larger and wound with 22% more superconducting cable, PF3 was finalized in two years and 9 months—a 15-month gain in fabrication time.

However spectacular, the operation on Tuesday felt almost routine: three self-propelled modular transport platforms, each equipped with a 180 kW power pack, worked in perfect coordination to move the 375-tonne component, carefully wrapped in protective plastic, to the storage building. The ride from the Winding Facility to the storage area was short—less than 45 minutes, including the traditional photo session to immortalize both the event and the great human and technological adventure it represented.

For all those present, whether associated with the ITER Organization, Fusion for Energy, or any of the half-dozen contracting companies whose name was inscribed on the coil's protective wrapping, it was a moment of legitimate pride. Few industrial ventures compare to the making, in record time, of first-of-a-kind components of such size and complexity.

See this report on the Fusion for Energy website.