Design concept for cryoplant system approved

8 Oct 2010

-

Luigi Serio, Cryogenic Section Leader

The ITER machine will rely on a large and complex cryogenic system comprising the cryoplant, which will produce the required cooling power, and a cryodistribution system which will distribute the coolant. The cryogenic system will guarantee cooling and stable operation for ITER's magnets, its cryopumps and its thermal shields over a wide range of plasma scenarios.

The magnets operate at high magnetic fields to confine and stabilize the plasma and require cooling with supercritical helium at 4 K (-269 deg C). They will be surrounded by a large cylindrical cryostat and an actively-cooled silver-coated thermal shield with a forced flow of helium at 80 K. Large cryosorption panels cooled by 4 K supercritical helium are used to achieve the high pumping rates and vacuum levels.

The design review panel with representatives from the various interfacing divisions, the Domestic Agencies and the cryogenics team at work during the three-day meeting.

The key design requirement of the ITER cryoplant is to cope with large dynamic heat loads deposited in the magnets due to magnetic field variation and neutron production from deuterium-tritium fusion reaction. At the same time, the system must be able to cope with the regular regeneration of the cryopumps.

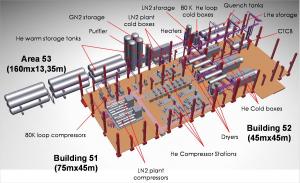

Last week a team lead by Hans Quack, professor for Refrigeration and Cryogenics at the Technical University Dresden, Germany, thoroughly reviewed the conceptual design of the cryoplant system. The cryoplant system will be installed in two buildings and an outdoor area. It is composed of helium and nitrogen refrigerators combined with an 80 K helium loop. Storage and recovery of the large helium inventory (24 tonnes) is provided in warm and cold (4 K and 80 K) gaseous helium tanks.

Three helium refrigerators supply the required cooling power via an interconnection box providing the interface to the cryodistribution system and redundancy of operation between refrigerators during faulty scenarios. Two nitrogen refrigerators provide cooling power for the thermal shields and the 80 K pre-cooling of the helium refrigerators.

The reviewers could not identify any flaws in the design. The whole review panel was instead impressed of the amount of good work done and encouraged the cryogenics team to continue in the same direction. The approval and recommendation of the cryoplant conceptual design opens therefore the door to the procurement of the largest cryoplant system in the world. The Liquid Nitrogen Facility (LN2) and auxiliary systems will be procured by Europe, the Procurement Arrangement is expected to be signed in December this year. The Liquid Helium (LHe) plants will be directly procured by the ITER Organization with a call for tender issued during the first half of 2011.