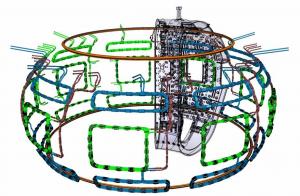

Design of ITER's in-vessel coils converging

Each in-vessel coil is wound from about 50 metres of conductor consisting of a 59-mm outer diameter stainless steel jacket, an insulating layer of magnesium oxide and an inner copper conductor. Magnesium oxide is chosen for its ability to withstand the harsh radiation environment within the ITER Tokamak. Water will flow through the central hole to remove power deposited from resistive and neutron heating. In total, the in-vessel coils require more than four kilometres of mineral-insulated conductors.