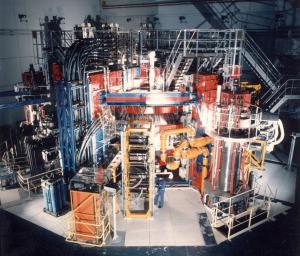

Tore Supra looking WEST for the second ITER divertor

17 Dec 2010

-

Mario Merola and Richard Pitts

Tore Supra might help to deliver answers for the second divertor set foreseen for the nuclear phase of ITER.

During the non-active phases of operation, ITER will use a divertor with carbon and tungsten plasma-facing material. Carbon is the reference design solution for the lower part of the divertor targets due primarily to a long history of experience in present and past tokamaks. Beginning with a carbon target is considered to have several advantages for the start of ITER operations, given its proven range of compatibility with a number of plasma conditions in present devices, particularly at low densities with significant additional heating. Its use will considerably ease the development of techniques for the control and mitigation of plasma instabilities (edge localized modes and disruptions) which, even in the lower power conditions characteristic of the non-active phases of ITER operation, can generate heavy heat pulse transients.

Unlike carbon, which sublimes, tungsten melts and there is a real concern that the very short duration, high heat fluxes that can be deposited during these transients will yield deformations of the precise material surfaces, compromising subsequent operation.

Largely due to the high level of tritium retention expected as a consequence of fuel co-deposition with carbon eroded from divertor target surfaces, ITER intends to replace the first carbon/ tungsten divertor with an all-tungsten variant before the start of the deuterium and deuterium-tritium plasma operation phases. However, the required high heat flux tungsten technology has never been tested in the demanding environment of a tokamak under the steady state plasma heat fluxes (~10-20 MWm-2) expected on divertor surfaces during ITER fusion plasma operation. Moreover, the fabrication of the ITER divertor with full-tungsten armour in the high heat flux strike point regions, represents an unprecedented technological challenge.

In order to reduce the risks and anticipate any difficulties ITER may face in terms of manufacturing or operation, the CEA IRFM laboratory, ITER's neighbour on the Cadarache site, has recently proposed to equip Tore Supra with a full tungsten divertor, benefitting from the unique long pulse capabilities of the Tore Supra platform, the high installed power and the long history of operation with actively cooled, high heat flux components. Since Tore Supra is a circular plasma device, operating with a full toroidal limiter surface, the proposed upgrade requires that the device be equipped with some additional in-vacuum vessel magnetic coils to allow the production of divertor plasma shapes, just like those which ITER and all other divertor tokamaks use.

This tungsten divertor project, named "WEST" (acronym derived from W Environment in Steady-state Tokamak, where W is the chemical symbol for tungsten), promises to bring answers in a timely manner for the second divertor set foreseen for the nuclear phase of ITER.

A feasibility study of the WEST project was launched on 25th February 2010 and has involved about 40 people. About 500 components with a total of 15,000 tungsten tiles are planned to be manufactured with a fully relevant ITER design and technology.

The 164-page Feasibility Report was the basis for a peer review held at CEA Cadarache on 8 December 2010. An international review panel was called by CEA and was chaired by Prof. Minh Quang Tran (CRPP-EPFL, Lausanne, Switzerland). It comprised experts from Europe, China, the US and from the ITER Organization. The conclusions of the panel will be delivered early next year.