Touring hot cells in CEA-Marcoule

4 Feb 2011

-

Alexis Dammann, Hot Cell and Radwaste Facilities Integration Section

"In a hot cell environment, the simplest solution is always the best... " This was one of the recommendations made by nuclear operators in CEA-Marcoule to a delegation visiting from ITER.

The five-person ITER delegation visited three nuclear installations in Marcoule: Atalante, Phenix and Melox.

Atalante is a facility that is dedicated to research and development in the field of spent fuel, from dissolution to vitrification. The delegation had several discussions regarding maintenance operations and rescue scenarios.

The "red zones" in the installation are not accessible for safety reasons and all operations are performed remotely. For the operators, any type of failure must be considered at an early stage of design. If design fails to anticipate the consequences of a failure, the hot cell can be rendered unusable during shutdown and recovery operations can become very costly.

While much smaller in scale, the hot cell in Phenix has many similarities with the planned ITER Hot Cell Facility. Composed of two units—one on the ground floor and another at basement level—maintenance areas are localized on the first floor.

Despite its compact design, Phenix's hot cell layout was flexible enough to allow the addition of a second cell after a few years of operation. Cells are filled with inert gas (nitrogen) to prevent hazards arising from the presence of sodium on the fuels. Phenix is a fast neutron reactor prototype that uses liquid sodium as coolant.

Melox was the third nuclear facility visited by the delegation. The installation manufactures fuel assemblies destined for light water nuclear reactors operating on MOX (mixed oxide fuel), a nuclear fuel elaborated from a homogeneous blend of uranium and plutonium oxides.

Alexis Dammann, Virginie Beaudoin, Victor Ivanov (CCS), Andrew Gray and Atsushi Onozawa (visiting researcher) stand at the entrance of the Atalante facility in CEA-Marcoule, some 30 kilometres northeast of Avignon.

Safety, availability and efficiency are key drivers for the operators. Production in Melox (200 tonnes/year) has doubled since 1997. The operators emphasized the advantage of implementing proven and robust—sometimes referred to as "agricultural"—technologies, and also highlighted the need for automation and remote control for optimized production.

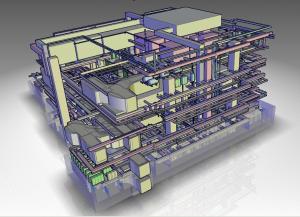

The ITER Hot Cell Facility will be one of the largest in the world. Because of the size of the components to be handled and maintained and also the complexity of some of the processes, the challenges to be faced are considerable.

Visiting similar facilities, building on lessons learned there, and benefitting from feedback is absolutely crucial to optimizing the design of a safe Hot Cell Facility for ITER.