New conductor developed for ITER's in-vessel coils

9 May 2011

-

Sabina Griffith

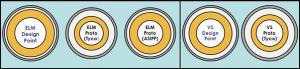

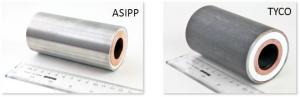

A comparison of the ITER Design Point and the actual size of the near-scale conductors provided by ASIPP and Tyco. This conductor, the largest of its kind ever, consists of a stainless steel jacket, magnesium oxide insulation, copper alloy to conduct current and a water-cooling channel in the centre.

The question of how to improve control of edge localized modes (ELMs) and the vertical stability of the ITER plasma will be one of the key issues addressed in next week's meeting of the ITER Science and Technology Advisory Committee (STAC). And there will be good news to discuss. In the six short months since the Preliminary Design Review performed in October last year, the in-vessel coil design team led by the Princeton Plasma Physics Laboratory (PPPL) worked with two suppliers from Canada and China to fabricate the largest stainless sheath mineral insulated conductor (SSMIC) ever produced in the world.

ASIPP and Tyco conductor samples, 100 mm long. Once received at PPPL, the prototypes were cut, pushed, pulled, bent, heated, electrified, sliced and x-rayed to evaluate their mechanical and electrical properties.

"Because of their proximity to the plasma, conductors with conventional insulation schemes were not an option for the in-vessel coils," says Edward Daly, the mechanical engineer who led the design efforts. The team therefore decided to choose SSMIC for its ability to withstand ITER's high radiation and bake-out temperatures of 200 °C.

The sheer scale required for the ELM and vertical stability coils in ITER, however, is much larger than anything produced previously. In June, contracts were awarded to the Institute of Plasma Physics at the Chinese Academy of Science (ASIPP) based in Hefei, China and to Tyco Thermal Controls, Ltd in Ontario, Canada, who both developed prototypes within four months. Once received at PPPL, the prototypes were cut, pushed, pulled, bent, heated, electrified, sliced and x-rayed to evaluate their mechanical and electrical properties.

"In general, the conductor samples performed as we had hoped and expected," says Ed Daly. "There were no show-stoppers, but there is still work to do." The results will be used in the final design and prototyping phase, planned to start in July. ASIPP has expressed interest in manufacturing these coils and has proposed collaboration with PPPL.

ITER's in-vessel coils—another example of world-spanning cooperation.