A component’s odyssey

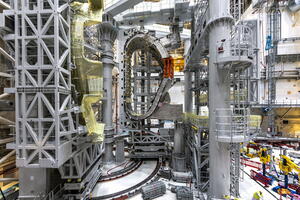

Even after delivery to ITER, a vacuum vessel sector faces a long path before it can be mounted in one of the tools in the Assembly Hall to become a “sector module” or ultimately installed in the tokamak assembly pit. The 440-tonne components need to be tested then “equipped” with hundreds of studs and supports for sensors, cable looms and various measuring devices and prepared for handling by the overhead cranes. The dimensional non-conformities that were detected in the first three sectors to arrive on site, however, resulted in significant detours from this carefully planned roadmap. For sector #8, the most affected of the lot, the "detours" were particularly complex and numerous. From the moment sub-assembly was interrupted in December 2023 to August 2025, when the sector was back in tooling and sector module assembly could restart, its onsite odyssey lasted 20 months.

When faced in 2023-2024 with the necessity of repairing three vacuum vessel sectors in parallel, the teams were confronted with daunting challenges. The equipment in the Assembly Hall could only handle two module assembly operations at a time—or, in this very specific case, two repair operations. Because of the planned insertion sequence of sectors in the pit, it was decided that sectors #6 and #7 would be repaired in the sub-assembly tools vertically, to be completed first, while sector #8 would be repaired in the recently vacated Cryostat Workshop where ample space was available.

To cope with this unanticipated situation, new procedures had to be defined and tooling adapted. The massive component, as heavy as a fully loaded jumbo jet, needed to be released from the arms of the sub-assembly tool where it was located, pivoted from vertical to horizontal (a reverse “upending”), and transferred to the nearby workshop.

However lying on a bespoke steel platform in the Cryostat Workshop, sector #8 would only present one of its sides to the workers and machines tasked with restoring the nominal geometry of its bevel joint regions. Once repairs were finalized on one side, the component would need to be “rotated” in order to make its other side accessible.

The highly complex and spectacular handling sequence was carried out in March 2025: the upending tool moved the component from horizontal to vertical; the double overhead bridge crane lifted it and rotated it 180 degrees above the tokamak assembly pit before docking it temporarily while the upending tool was reconfigured for its return.

Fourteen days later, sector #8 was back in the upending tool and could be returned to the Cryostat Workshop—this time with its second side exposed.

Another six months of patient work involving high-tech robots and highly skilled workers and the long parenthesis could be closed. Vacuum vessel sector #8 is now back in sub-assembly tooling to be equipped with its thermal shield and paired with two toroidal field coils. It is scheduled to be back inside the tokamak assembly pit in February 2026—for good this time.