Orders placed for second-stage converter systems

Forty-four power converter units are tasked with “stepping down” and converting the AC voltage arriving from the ITER switchyard to the precise voltages required by the individual magnet systems. Outside of the Magnet Power Conversion buildings, 32 units procured by China and Korea under Procurement Arrangements are already undergoing commissioning. Major Task Agreements for the remaining systems were signed this summer.

Outside of the Magnet Power Conversion buildings on the ITER site, power converter transformers installed in individual bays bring down the voltage received from the switchyard to lower voltage levels required by the ITER magnet systems. Inside the building, each unit is paired with a large rectifier whose function is to convert AC voltage to DC voltage; once the voltage has been "rectified," it can be fed to individual magnet systems through steel-jacketed aluminium busbars. Thirty-two converter units are already in place, but the coil power converter system requires 12 more before the machine can turn on for the Start of Research Operation (SRO).

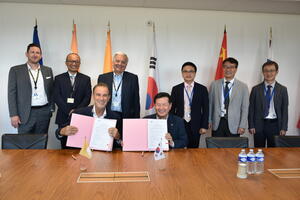

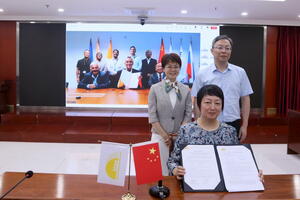

A significant milestone for the coil power converter system was reached this summer with the signature of two Task Agreements for this complement of equipment.

On 19 June, the ITER Organization and the Korean Domestic Agency signed a Task Agreement for six units of central solenoid AC/DC power converters and the upgrade of the master control system for the integration of stage 1 and stage 2 systems. The equipment will be manufactured by Dawonsys Co. Ltd, the company that already supplied 18 power supply units and the master control system (stage 1). The scope of the Task Agreement includes design, prototyping, manufacturing, integrated testing, and on-site commissioning of the stage 2 systems.

Two months later, on 19 August, the ITER Organization signed a Task Agreement with the Chinese Domestic Agency for two units of poloidal field AC/DC power converters, four sets of vertical stability coil AC/DC power converters, and the DC interconnecting busbars that will link stage 1 and stage 2 converters. The equipment will be manufactured by a consortium led by the Institute of Plasma Physics, Chinese Academy of Sciences (ASIPP), and that includes the Southwest Institute of Nuclear Physics, Rongxin Huike Electric Co., Ltd., China Nuclear Power Engineering Co., Ltd., and China Nuclear Industry 23 Construction Co., Ltd. Task Agreement scope includes the design, prototyping, manufacturing, integrated testing, and on-site commissioning of these systems.

The Task Agreements for stage 2 main coil power converters were concluded six months ahead of schedule, reflecting a strong level of collaboration between the ITER Organization, the Domestic Agencies, and industrial partners and demonstrating the commitment of stakeholders to achieving the ITER 2024 Baseline.