First coil ready to face deep-space cold

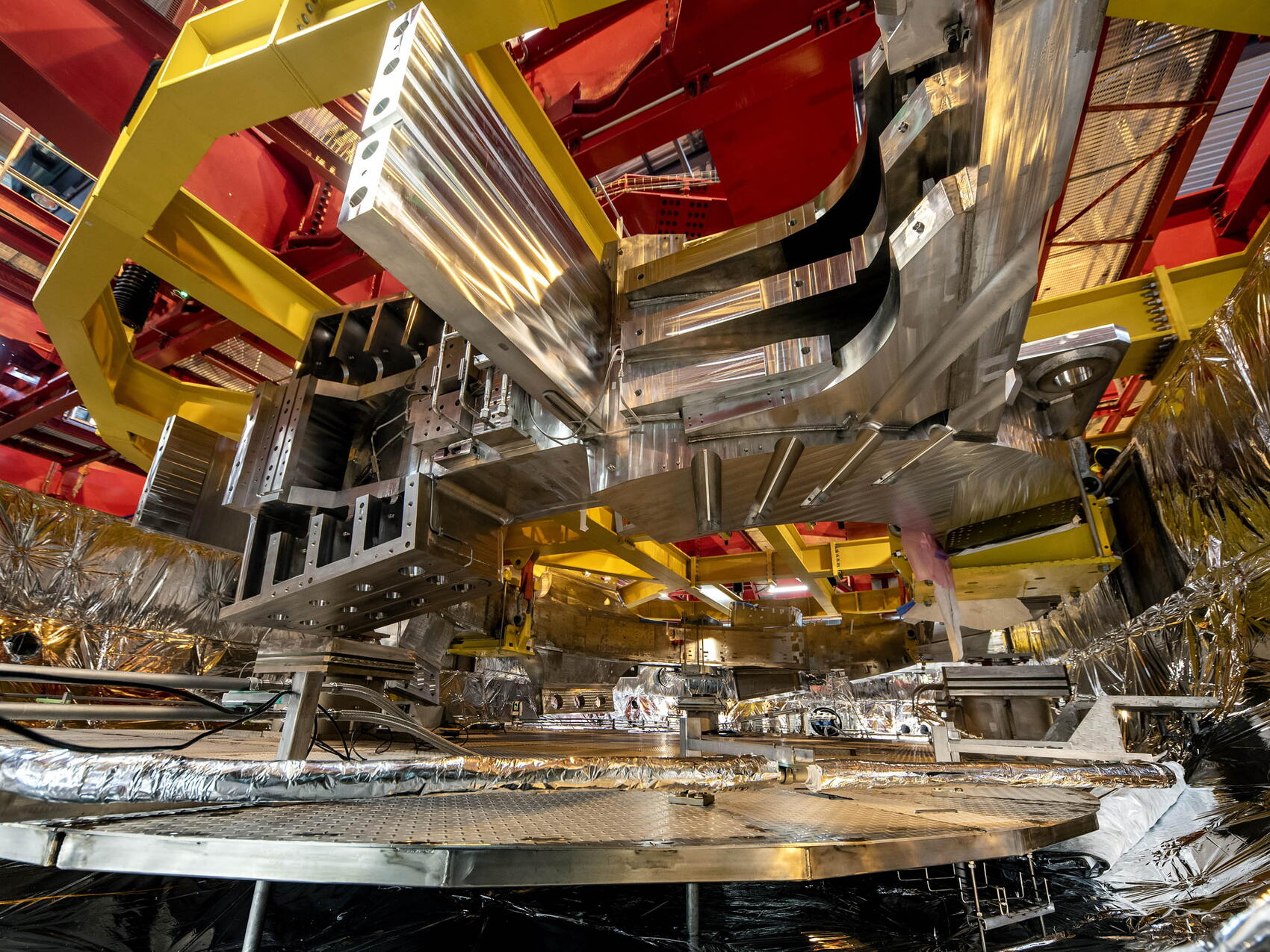

For toroidal field coil #7 (TF07), winter will be short but exceedingly harsh. For one full month, the ~ 300-tonne component will be enclosed in a steel cocoon, its temperature brought down to 4 K (minus 269 degrees Celsius)—an environment as cold as that of deep space. On Monday 15 December, the big red tower crane that had handled the ITER poloidal field coils in the final stages of their fabrication carefully deposited TF07 in the sardine-box-shaped cryostat, the central element of the recently finalized magnet cold test facility.

Toroidal field coils have already experienced extreme cold. Once finalized, in Japan or in Europe, most of them were tested at 80 K (minus 194 degrees Celsius) before being shipped to ITER. Testing at 80 K is a relatively simple operation that provides precious information on the thermal and mechanical constraints that a coil will be exposed to during its lifetime. Testing at 4 K, which is the operating temperature of the ITER superconducting magnetic system, is a completely different operation that requires a massive infrastructure: a large insulated cryostat, powerful cooling and power systems connected to the coil by a real ITER feeder, and all the required command and control instrumentation.

“At 4 K, the winding inside the coil becomes superconducting, which allows us to circulate a strong electrical current and thus generate an intense magnetic field,” explains David Grillot, ITER manager for the integrated commissioning program. While parameters inside the magnet cold test facility do not completely reproduce the conditions the coil will face during the machine's operational phase, they come close enough to enable, in David’s words, “a partial but real-scale commissioning of the tokamak's magnetic system.

An effort that began more than two years ago has reached its culmination. The magnet cold test facility, along with the cryostat that constitutes its most spectacular feature, and the bespoke spreader beam that interfaces with the tower crane were built and delivered in record time.

As 4 K testing requires time, and vacuum vessel sector module assembly is progressing particularly fast (each module comprises two toroidal field coils), the teams anticipate the possibility of testing 4 to 5 coils, including the smallest poloidal field coil PF1 which can fit into the cryostat without major adaptations.

Along with minimizing risks, this partial commissioning of the coil ecosystem will be like a general rehearsal that will save the project a considerable amount of time.